Drop one and find out…

No, wait…

When your blaster retailer or tech tells you that your broken blaster is irrepairable, don’t just take their word for it… please.

If I had a buck for every “hopeless case” blaster across my workbench that was fairly easily resurrected and ended up back in good working order, I’d have a wall full of Ares M110 DMRs and Tavor TAR21s. ![]()

Case in point… BME’s X-Force Thompson SMG, snapped in two at the magwell just in front of the charging handle. After repair :

Retailers and techs will always weigh effort vs reward and cost effectiveness into their evaluation of a repair, and that’s fair, they’re running a business with bottom lines to consider, and let’s be honest, it’s far better for them if you just buy a replacement… but just because it doesn’t meet their criteria for a cost effective repair doesn’t make it a lost cause. ![]()

Moral of this long winded post? Always get into it and have a crack… you’ve got nothing to lose and everything to gain. ![]()

How did you go about that? Enquiring minds want to know ![]()

Hit the nail on the head regarding time/costs VS replacement of broken parts ![]()

This was also a major consideration in my Hot Rod/Classic Car business as well as the Gelblasting Hobby.

Plenty of good bargains to be found with items that are easily repairable if you have the skills to do it yourself, but commercially unviable if you had to pay someone else to do it!

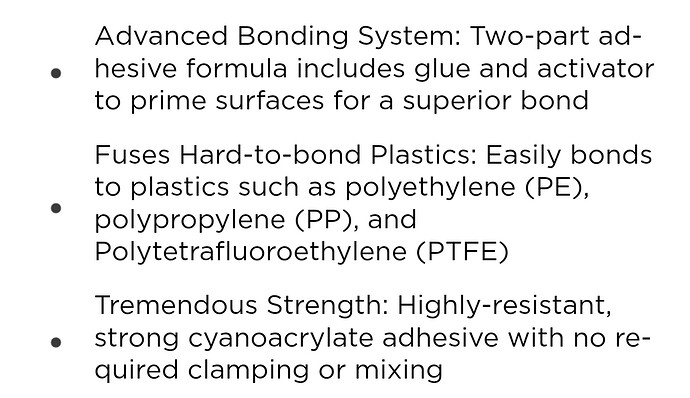

This stuff…

I used to use it a lot when I was working at a test engineers down in Mexico on plastic auto.parts, really good CA for difficult plastics. Higher strength too. ![]()

Must get some more… used the last of it on this Thompson. I see a trip to Repco in my immediate future ![]()

Nice, put that in my box of tricks ![]()

Nice work! It is always possible to repair or rebuild! Up to the owner if they are willing to invest the time and or money!

My experience is: for yourself it is always worth the effort… gives you time in the hobby and I love a long winded project!

Especially if it keeps busy for a few weeks! Very satisfying.

When I worked for a retailer the conversation with the customer: I can fix anything, but are you willing to pay for my time and parts when a new one is the same or less than the repair? Is this blaster still available or is a better blaster available for less than the repair etc. I never made the choice and always gave all the options.

It always comes down to how much they liked what they had. I remember going all out on a gen8 Barret for a customer because it was his first blaster and he loved it. He attempted some upgrades and broke a lot of things it was quite a mess.

It was in pieces missing bits and had a lot of broken internals and externals, but I got back together, smacking hard and fast. And he loved it. It cost him way more than a sensible person would have payed for it but it had sentimental value and at the time was no longer readily available new.

For me, I love getting broken trash and making something good or cool out of it.

I had the same with some of my customers.

You get both ends of the scales where one customer balks at the quote for repair/upgrades being more than they paid for the actual blaster itself, whereas others were happy to continue on with doing whatever work was required to keep their beloved favourite cheap blaster working as best as possible no matter what the cost ![]()

![]()

I’ve often had this discussion with my mate at Oz Gel & Testicle… you have to apply the law of diminishing returns to repairs. Which is why I haven’t gone down the path of teching as a financial sideline.

As Roksolid said, it can be justified if there’s an attachment to the blaster. I’ve lost count of the hours I’ve poured into my F2000 and EVO3, but those crappy little ABS units have a lot of nostalgic value to me, so I’m happy to do it.

I’m just grateful that I have a decent enough skillset that allows me to do what I want in a passable manner without forking out tons of shekels to someone else. Otherwise I’d be broke. ![]()

V3, for the banned states…??

Get yer rubber bands, ere…!!

I’m seriously thinking about one of those ROKR Thompsons just for shits’n’gigs. ![]()

Be fun putting it together too… from what I’ve seen online they do require some fettling to make them work.

Sounds right up my alley. ![]()

IIRC you mentioned the other day you have a straight handguard and lighter outer barrel for this Hanke Thompson, @BME ?

I think we talked about how it would be safer to run that hanguard rather than the vert grip so that you’re reducing the amount of leverage you’re likely to put on that repair.

You’ll have to keep in mind that if by design that area’s a weak point when it’s not compromised then no matter how good the repair is, it’ll still be a weak point. ![]()

It might have to stay as it is.

I only have a stock, left over.

I think I threw out the other spares, from the thommy sacrificed for the PR, some time ago…

It should be fine, for a gangsta suitcase dweller…

Where did you get the silver stuff from? Time to dress up the MP5K

its called " rub n buff". Silver leaf.

get it from spotlight…about $14 a tube.

Be warned, its finicky to work with.

Your trying to avoid a ‘big first blob’, which cant be spread too much.

a) wear disposable gloves.

b) the teeniest dab, on your index finger, then apply… it smears then sets. Hard to spread from initial dab.

c) rub/ buff with another finger. once it gets to a light smeary layer, you can rub that elsewhere safely

d) start on corners / edges of holes first. This disperses the first “blobby dab”, into a safer bit to work with. Circle around holes etc first…

e) rub back later. To fully remove, i use cleaning chemwipes.

have a practise first, then have fun…!!

@Wombat …

You got me in the weathering mood…

Here is my JM mp5-k done… a light weathering.

You’ll quickly see, do the initial dab on raised bits… screws, switches, corners etc, and spread from there…

@Wombat …got some of the silver buff, yet…?

Given it a hit.?

Put up some pics if you have, keen to see…!

Not yet - Have friends from US arriving next week, so current focus is on “decluttering”