Time for a minor collaboration on @BME 's Barry Burton clone. ![]()

As good as the Hitman compensator looks standard, BME wants side vents to make it look even cooler. Normally milling a few slots into aluminium would be very simple, but with no Bridgeport available, it’s a by hand operation. Ah well, no guts no glory, as they say. ![]()

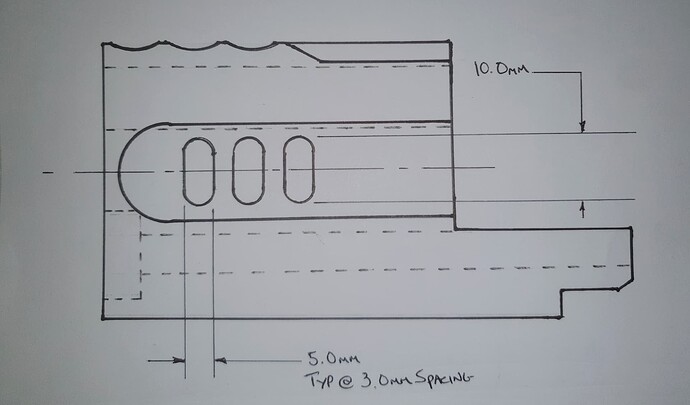

I measure everything up to work out where these slots can go without interfering with recoil guide rod bores, barrel bores, etc. then sketch out a rough 2D representation of what it is.

The rectangle around the text provides a handy frame to work within to locate the three vents in a visually pleasing position.

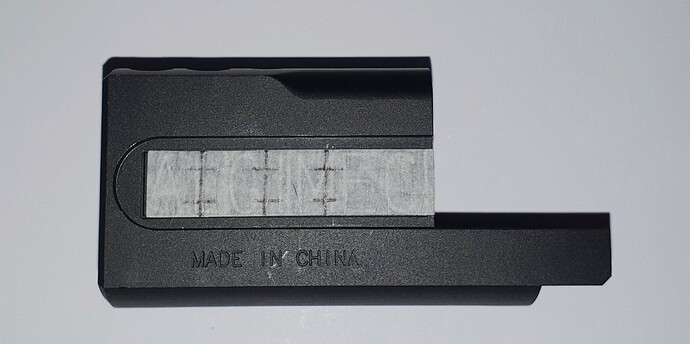

I mark out the location of pilot holes. This is hand filIng, so the more I can drill, the less I have to file. A little masking tape lets me draw hole locations then I mark through the tape with a centre punch to locate where I drill with a 3.0mm drill bit.

Off to the drill press to pilot drill with a 3mm drill bit. The top hole of the first slot was into a void left by the top vents so no full pilot hole for that one. Drill bits will always pick the path of least resistance, and would have run off on an angle, so that slot will have to fully filed from the bottom hole up.

Into the bench vice for filing. I use a 4mm chainsaw file to file out the slots using the reference line around the text to keep everything square, vertical and even. Slow and steady’s the go here, you can’t put back what you take off. It also pays to file from both sides alternately just in case there’s a bias in your filing technique.

All filed out with a light coating of black, ready for stamped letter filling and pic rail attachment. The front slot is shorter because it ran into the top slot, the void made filing a nightmare. Ah well…

Trial fit onto BME’s Taurus and everything’s looking good so far.

Tomorrow I wet set the pic rail to the bottom of the compensator, finish filling the lettering and any gaps around the pic rail before final paint. ![]()