Righto, commitment time!

So on the weekend I bought one of these.

I will start with an initial review, and then move to what I do best through the coming weeks and play with it’s insides.

In the box:

The blaster

Metal cyma STANAG mag

outer barrel entension

gel bottle

cheap safety glasses

gold packet milky looking gels

plastic barrel cleaning rod

The barrel cleaning rod was an awesome surprise for me, it is something that we should have given the amount of ultra hard gels I have seen jammed in broken blasters in the past couple years. Don’t clear your jam with your trigger finger kids!

No battery or charger here. And honestly, that is not a bad thing. Included “free” batteries and chargers are garbage anyway, and both are things I recommend getting a proper balance charger, and decent quality batteries that suit you application, not a generic free inclusion.

Externally:

Awesome. Very little play and movement in the blaster. It is all metal except the A2 pistol grip and crane stock. Cyma’s crane stocks are great for fitting larger Titan nunchuck batteries, allowing for more capacity without external mounting of batteries, so you can keep the replica look; something I value highly. You could also store three smaller lipo batteries and just remove the rear pad to swap connectors. It is nice to have options. Aesthetically the stock is something I like anyway so this is win win.

The standard A2 pistol grip does not appeal to all people, but it does to me as they are great at motor/pinion alignment. Almost like the system was originally designed by Tokyo Mauri way back when using an A2 grip. Also for the aesthetics of this replica, is suited well.

The barrel is very secure, as is the RIS handguard. The sights are nice, and rear CQB model sight is good for mounting a red dot style sight and still retaining the iron sights. Again nice to have options. Something does trigger me about having the front triangle sight with not partner on the rear if mounting an optic by removing the carry handle, again just a nice to have. I may get a full carry handle yet.

The flash hider can be removed with a small grub screw then standard 14mm ccw thread off. There is also a barrel extension, for those wanting a standard length M4A1 rather than a CQB, or in my case those wanting to mount an M203!

The standard inner barrel is 285mm long, with a step down that fits into the flash hider in CQB configuration. Sadly, you can not fit any style of hopup with the standard flash hider. The muzzle itself is tapered inside and too small to fit anything in, and the extension is just too tight to fit a sweetheart style hopup into. Unfortunately, this means I am going to have a different flash hider just to get a hopup, though I may still explore modification to the barrel extension for fitting a sweetheart hopup as it is almost large enough. We will cross that bridge in the build.

And of course, my short M203 is already on there.

Initial performance:

I had mixed feelings with straight out of the box performance, some of that is my fault, and some the manufactures. The only gels I had to try ready at the time were either old Ultra Elites, or old Predator v2s. Two months old actually. Knowing what happens with old elites in AEGs I opted for the safe option of the smaller predators. Gave them a quick “moistening”, in the mag and off I went. A couple of gels down range in the garage and it stopped firing.

“F*****g cyma mags already!” I thought… pop the mag out and there in the feed tube was some shrivelled up old dried out milky white gels. I opened the mag, and there were quite a few. Disappointing, especially as someone who has worked in the retail/tech side I know this would lead to an annoyed customer interaction on the phone then in the store. Also have I voided my warranty by opening the mag? Yes. I don’t care, but a newer less experienced customer would! Anyway…

Once the mag was dealt with it fired fine. Very standard performance for a $400 blaster. Averaging 280fps, exactly what X-force’s page says they got with the Predator V2 gels.

I didn’t get a photo with the full size Ultra Elite gels, but they were closer to 300fps average, and the old Ultra Elites did indeed jam a few times as I expected, but anyway… it isn’t like I wasn’t expecting that!

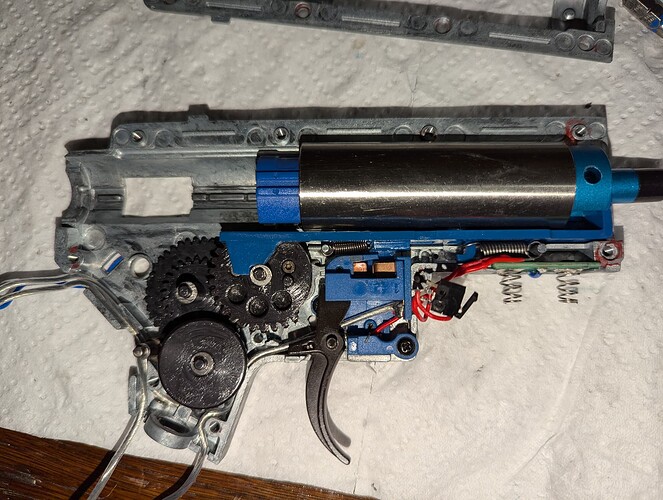

The blaster actually sounds like the motor height is set well and the shimming sounds bob on. I will verify this when I open it up, but it looks like CYMA has stepped up it’s game here.

COMING UP:

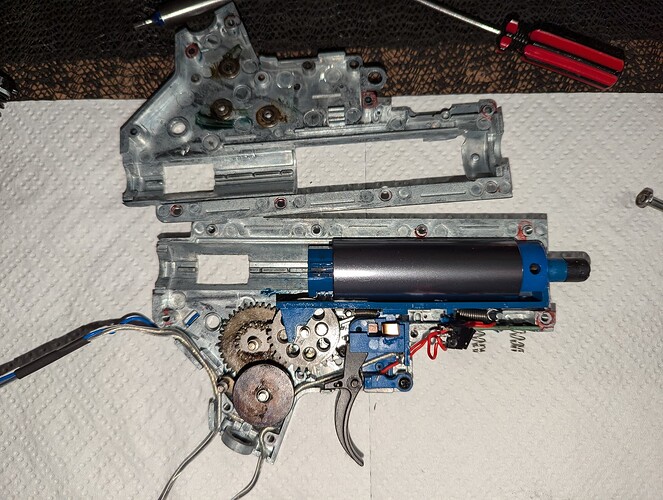

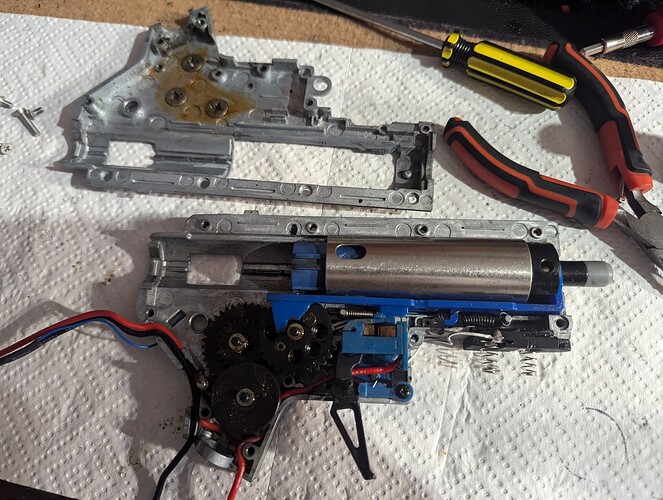

You all know I am getting inside this thing and further voiding my warranty ![]()

Experienced tinkerers know, you don’t get a CYMA metal gearbox blaster for how it performs in stock form. You get it for what it can become with a few parts!

I haven’t been inside a CYMA metal gearbox from this recent import batch, but we will get to that.

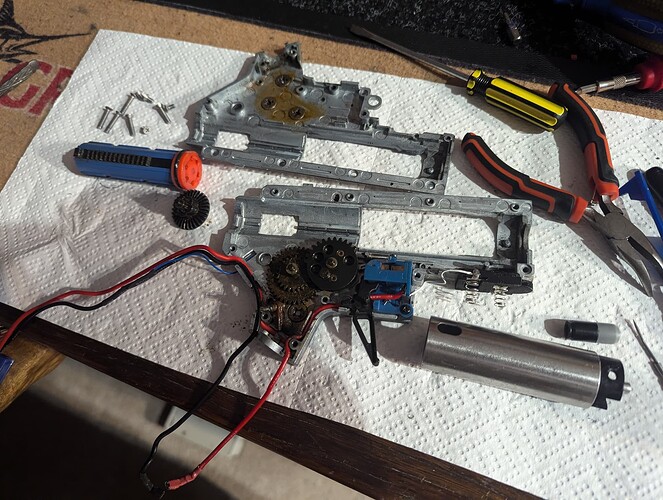

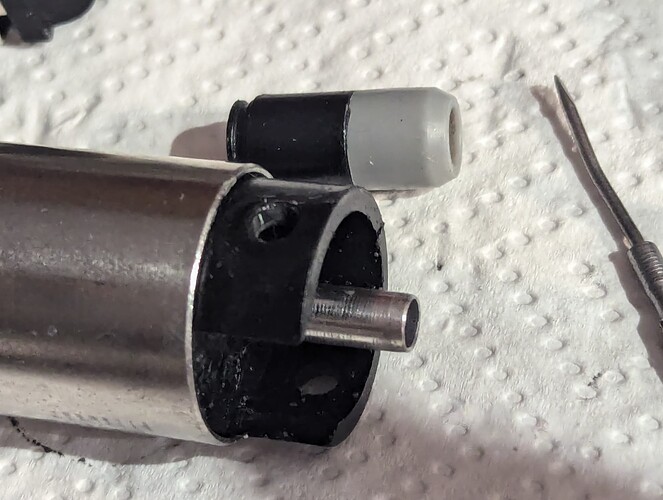

I have had the upper off already to eyeball the cylinder porting and yes, it is about a 70% port, which is fine for the barrel length. It is better if the seals are good, which judging by the chrono it is a little lacking there. I will be swapping to a full cylinder, and getting a barrel around 380mm to suit the extension.

If previous is anything to go by, o-ring will be needing a replacement, and the nozzle will not have a perfect seal. The gears used to be a typical “cast gear lottery”. Some would handle a faster motor, 11v and an m100, and the odd one would strip in stock form. Cyma pistons are pretty tough, built plenty with an m110 and close to 30rps with the stock piston.

Though the piston heads are REALLY on there, and the piston head is usually what I want to change, and since some just don’t come off, I usually ended up just replacing the piston as well, time is money as much as parts are here.

The standard motors were weak. Seriously weak. Just using an m100 will see a dramatic drop in rps, so this is going to go for me.

Generally, gears, piston and head, cylinder head and nozzle, spring and motor and these gearboxes are happy to over 30rps and close to 400fps.

MY BUILD PREFACE

The limitation for my build is going to be it needs a full stroke and cylinder with the longer barrel, so I won’t be going over 30rps on 11v. I also will be trying to keep it closer to "most field limits: of around 330fps, which will also help with some accuracy.

What I am actually going to be chasing is an efficient build, hoping to run an “army” stock with a normal size lipo, and get a lot of shots out of a smaller battery. Again, aesthetics are important on this one.

The one exception to this is going to be mags. I run SLR mags, so there will be some faffing to get them fitting nicely and feeding well. I will be designing and 3d printing an bit of an adaptor this time. Previously I would just change to LDT nozzle and tpiece, but this time I want to if my patience allows get the adaptor tube working.

It will have a snappy semi, and close to 11v rps a 7v battery, but with the option to be a little naughty on 11v if I feel like it. Reliable efficient consistent performance with decent accuracy is the name of this ones game. I am still deciding on how to do this, but I am thinking a warhead motor may be involved. I currently don’t have a good motor spare, so I am up for buying a motor, or changing the armature in another neo can to suit.