Don’t let that stop you mate!

That’s where I got a heap of real steel accessories ![]()

Here we go again with me giving away trade secrets and rambling on like a madman ![]()

![]()

Does anyone here actually do the water immersion break in procedures on their motors?

I only know of this from my experience waaaaayyy back when I was building custom RC Race Cars back in the early 1980’s.

Doing a proper water motor break in procedure was something that put your work/knowledge/reputation above anyone else in the hobby when it came to getting wins on the tracks with high end built RC competition racing cars.

I seriously only ever done this with maybe 3-4 of my own personal blasters, and never bothered spending that amount of time and effort on any of my customers blasters, because in reality, it wasn’t really viable as to the long term effects of such treatment.

Gelblasters simply cycle a piston in short bursts, whereas high speed RC Race Cars/Boats/Planes etc require full power, full revs and highest performance out of the motor 100% of the time.

To do the same water break in methods on a Gelblaster motor is nowhere near as important as the other hobbies mentioned for continuous high RPM use……… but the big advantage of performing this exercise was that it would increase the torque output of even a stock gelblaster motor by about 30% over standard! ![]()

Give the same treatment to a ChiHai rare earth magnet Red Motor……. and then they were pretty much indestructible and reliable for being able to pull back a bloody M250 spring if you really wanted to go that stupid!

Edit to add that I just did a quick google search and found that this article has a good balance of information between water breaking motors and opinions about why people don’t do this anymore ![]()

https://www.rctech.net/forum/electric-road/1010108-breaking-brushed-motor-wet-dry.html

https://www.rctech.net/forum/electric-road/1010108-breaking-brushed-motor-wet-dry-2.html

How is the cyma mp5? Is it equivalent to the famous $80 M4?. 460motor, nylon gears and box I’m guessing, i might grab one as a mod tester

Pretty decent and much the same as most other models from what I’ve heard about them, so nothing to lose in giving one a try ![]()

BING feng SCAR H MK17 on the bench today for some boxing day blaster madness…

Gearbox nicely shimmed and greased…

Interestingly this must be a later version, the earlier BF gearboxes didn’t have quick change piston spring access.

But the OEM spring… it’s the shortest one I’ve pulled out of any AEG. I was going to swap it out for a standard M90 but I believe when BF redesigned the gearbox shell they did a half arsed job of it… the spring retainer’s a bit janky and with the extra length it springs downwards and rubs on the metal gears, so the stock one’s going back in.

Took the opportunity to take out the fire select levers and the bolt release, ripped off the horrible BF paint and refinished with some nicer matt black.

While I was in there, I also disabled the ambi feature for the fire select… a really piss poor arrangement with so much play it was impossible to synchronise the detent pins and it felt so vague on operation. I figured one very functional select lever over two shitty ones is an easy choice to make.

I also pulled the rear stock apart, gutted it and made storage similar to a JM SCAR V2 for a decent lipo instead of the OEM arrangement which only provided for a tiny lipo. I’ve lost the ability to adjust the stock but it’s set to a position that suits me and is now solid as a rock… small trade off again for practicality and useability. Accessed by removing the adjustable cheek riser. ![]()

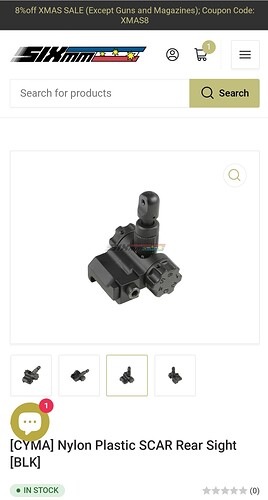

When this sucker’s all back together it should be decent, I’d put it up there as better than the nylon bodied CYMA SCARs for quality. ![]()

Thanks for sharing this, shows how much fun many of us are missing out from in this hobby ![]()

It’s looking great and sounds like it will be very comfortable, reliable and enjoyable to use after all of your modifications and improvements. ![]()

Spring Retainer Tilt:

Another awesome little design detail that will make or break any decent blaster build/design, and is a great subject for another one of my long rants ![]()

Rant away, Doc… ![]() let me start the ball rolling…

let me start the ball rolling…

When @LowGuido reviewed these SCARS a long time ago there were a lot of design flaws, but hey… Bing Feng. ![]()

The box LowGuido tore down was definitely a litle different to the box I just worked on… his had no quick change spring retainer, mine did. But it seems those talented designers decided they’d just reworked their shell moulds without too much effort and have actually made it worse.

What you get now is a VERY thin rear wall, poorly defined lug chanels and no way for the retainer to locate securely other than by those two lugs. Anything stronger than the short spring in it now and the spring throws all it’s forces downwards and into the gearset, which is probably why the spring’s so short out of the factory…

I did replace the pissy spring retainer with a beefier version, but seeing as how it’s got no way to seat squarely anyway it makes no difference, the spring still tilts.

The other scary design feature is an aperture, maybe a weird arse inspection window, moulded into the shell right below the location of the bevel gear bush holes. So you effectively lose about 25% of your locating hole… which, to me, is a huge design flaw. Just all up lazy Chinese engineering, but I guess Bing Feng are known more as toy makers than anything else so I guess it’s to be expected. ![]()

The only things about this particular V2 style box that’s really any different is the racked fire select plate for ambi and the nozzle for the proprietry t piece. I’ve disabled that woeful ambi anyway, so I’m seriously considering stripping it again, throwing the metal gears into a nylon CYMA V2 box and swapping out the selector plate and nozzle for the BF items.

Strangely, I do like the overall build quality of this SCAR… even the colour scheme, which at first glance looks incredibly wrong, is actually spot on identical to the real steel SCAR H MK17 you can see below, photo from the official FN Herstal website. ![]()

Great information and has jogged my cloudy old memory a bit further ![]()

I remember the cries of “but the colours are all janked up” when these were first released, but obviously comments from people who didn’t have a clue what the real rifles looked like and were probably used to just straightforward black or single colour tan blasters that were commonplace.

I do remember watching a few videos on their design and construction, and the lack of a quick change spring retainer has been the bane of many gearbox builders who always struggle reassembling them with the main spring locked inside ![]()

Was a common mod to ditch the original gearbox and replace with versions that had spring retainers to make life easier, but those gearboxes also had very bad designs and performance issues as well……… which is exactly what you have run into and can see why they were fitted with shorter weaker springs ![]()

Horizontal pegged retainers all have a major issue with tilting down and wreaking havoc on not only hitting the gear set, but I’ve seen even worse!

Another reason why I didn’t like some unequal spring design, that had their lightest windings directly in line with the tapered end of the spring retainer.

I had a couple of gearboxes destroy themselves when the retainer tilted down, had the tapered end actually pushed into and through the bottom spring windings, and then the whole lot caught on the back bottom edge of the piston as it was being driven backwards ![]()

Obviously piston locks up hard and solid with the spring coils and retainer jammed into the rear of the whole lot, and the motor/gears are already in full flight cranking everything rearward……. yeah, lots of things go crash/boom/bang and little pieces are created in a big hurry!

Some aftermarket early gearboxes I used still ran standard 2 lug retainers, but the smart designers rotated the lug locks to run vertically in the back of the gearbox, not horizontally, which were much sturdier considering that the retainer/spring flex was limited to a side to side motion, not upward or downward within the gearbox.

Naturally the spring/retainer is contained very well from side to side movement inside the gearbox, compared with the large open space found above the gear set which allows the spring to enter into.

This retainer tilt issue was best “bush mechanic” fixed by fitting an alloy 2 lug retainer with the threaded rears, which were used in blasters that ran bolted on buffer tubes.

(EDIT: Just noticed that you have the ultra crappy design box/retainer that has those jokingly thin/narrow lugs as well!

You hit the jackpot being inflicted with those bloody things ![]()

But not is all lost, as to run the modified alloy retainers I mention, their larger/thicker lugs can be easily filed down to size to allow them to be used in these types of gearboxes.)

The issue with models like the SCAR/ACR/UMP45/AK/MP5’s etc etc and anything else that didn’t run AR/HK style bolt on buffer tubes is that none of them had threaded spring retainers and relied purely upon the 2 lug design to maintain spring/retainer stability. ![]()

The bolt on buffer tubes provided very solid and stable support for keeping their spring retainers in perfect alignment in comparison to those without.

So would fit bolt on type retainers to the gearboxes that didn’t have them, and then allowed to run a large washer and bolt from the back of the gearbox and into the retainer to firmly hold them in place and fix the retainer tilting problem.

It might take a little bit of fiddling to get the exact right size/number of washers sorted, as well as the bolt length, plus sometimes a bit of dremel work at the back of the receiver for clearance in some occasions, but the results were definitely worth it to keep the gearbox operating smoothly and keep them in one piece! ![]()

The next greatest invention might have been from CYMA, or one of the other reputable manufacturers, who bought out 4 lug spring retainers, that were also offset 45° from vertical once inserted and locked into place, which were extremely stable and stronger locking/retaining capabilities. ![]()

I’m very rusty on specifics memory wise, especially after so many years and hundreds of different gearbox builds/brands/models/designs as to what was what, but all this stuff is still handy knowledge for things to look out for when looking for parts and building different boxes.

Oh…… yeah…… and why does that scope look backwards? ![]()

![]()

Great info there, Doc… very much appreciated insights into this really annoying issue… particularly the alloy bolt on threaded retainer. I have a couple of those lying around, might be a good day to get creative tomorrow. ![]()

Oh, and that scope’s not on backwards, Doc… ![]() it’s a Spina Optics LPVO, low powered variable optic. Used a lot on DMR real steel, not holo or red dot reticule, actual crosshairs with a zoom range that’s a bit more gel blaster friendly. Eye relief’s at the fat end.

it’s a Spina Optics LPVO, low powered variable optic. Used a lot on DMR real steel, not holo or red dot reticule, actual crosshairs with a zoom range that’s a bit more gel blaster friendly. Eye relief’s at the fat end. ![]()

Trust me, my friend… if I mounted it the other way, I wouldn’t be able to see shit. ![]()

Yeah, I was being a little bit sarcastic about the scope comment, and with my eyesight, it wouldn’t make any difference to me ![]()

Nice looking bit of gear though ![]()

Just had a quick look in one of the old spare parts boxes and came across these.

Very difficult ordering online as is very hard to tell the specific differences in sizes/details if the product description and photos are lacking ![]()

This is a classic example that shows the differences in thickness and sizes of the retainer and the lug sizes, also allen keyed units like yours compared with the threaded ones available.

Cheers heaps for providing the direction and advice for this retainer problem, Doc. ![]()

Took your advice and dug up an alloy threaded retainer this morning. It did require a little fettling of the retainer to fit the shell as you predicted and of course the judicious use of Loctite on the front and back screws but matched up with a tensile washer and a stainless M6 screw, it works a treat.

The retainer’s straight, solid and zero spring tilt now… with the added benefit of a bearing on the retainer and a full length M90 spring in there.

One more problem solvered. ![]()

Awesome progress updates, love the pics ![]()

Nice work mate, should definitely make a big difference and also makes those tiny lugged style retainers/gearboxes much more reliable ![]()

I see what you mean about that hole in the gearbox behind the bevel axle/bush, which were added to allow to be able to poke a screwdriver through to release spring tension by levering the AR Latch off of the bevel gear……. but was really a useless gimmick, because how hard is it to simply make sure that the gearbox is stopped with the piston all the way forward before disassembling anyways ![]()

Yeah I got a bit muddled with the problem with that bevel gear bush. Revisiting it again, it’s this that’s the problem…

The tenon grooves moulded into the shell that locate the grip have been moulded right up to the bevel gear bush hole but left open ended so you loose that much hole and the bushes are like a cock in a shirtsleeve… fall out every tear down.

The other problem to be fixed was the mag release arrangement. Normally, the mag release pin would go through a moulded lug on the gearbox to give it some stability, but not this one… the only thing that locates the latch end is the moulded housing for the ambi, and once activated it can come out too far then it’s just flapping around. ![]()

I’ve addressed that by bonding a plastic plate inside the receiver behind the ambi lever then drilling a tight tolerance hole to hold the whole assembly in line. The ambi function’s a bit tight now but the normal function’s 100% better.

Oh, and the only thing that secures the box to the receiver shell is the grip… no pin through the box to secure it in the middle, no retention at the nozzle end either. If you don’t shim the grip so that it’s tight to the receiver, when you wiggle the grip hard enough the gearbox moves in the receiver ![]()

Next one to tackle is whether or not I can do away with the rack setup on the fire selector plate and go to a more efficient cam fitted directly on the lever. It is much better since I disabled the ambi but still not as positive as I’d like it to be. ![]()

Sooner or later this project will reach critcal mass and then the old saying about polishing a turd will apply. ![]()

My favourite saying in life:

“You can’t polish a Turd, but you can always roll it in Glitter.” ![]()

It’s late, but I’ll get around to sharing more of my experience/knowledge/advice on how to fix those niggly little issues that you have mentioned to tackle next. ![]()

![]()

Turd polished… looks pretty good with the M203 fitted up, courtesy of DocBob. ![]()

Just waiting on mini Tamiya connectors in the mail, but it’s done. Overall, I would have been better off paying less for a CYMA nylon SCAR L, I wouldn’t have had to fix all the issues I’ve had with this Bing Feng… but then it wouldn’t be a MK17 with that big mag and I wouldn’t have had something to tinker with, so no regrets.

Certainly looking the goods and hopefully should be running much better ![]()

That M203 is a perfect fit too!

Got a set of 100:300 gears today, I know ppl have said they’re not as sturdy as standard gears cause of the way they intersect.

Mainly wanted to see if they were actually quiter and how they run, wasn’t going to put them into anything crazy either.

Do want to get a couple more of these tappetless cylinder heads and see how they go. First one I got seems to be doing good, was the cheaper of the 3 at $25, only put a couple mags through it thou.