Really, I’d shoot it and burn the thing if they weren’t worth so much ![]()

Just like a 428 in 70 Cougar. Take off rocker covers, unbolt engine mount, jack up engine, change spark plugs

I did somethong like that with an old M4 for shits’n’gigs years ago…

Ugly as sin but kind of unique at the time. It ran a modified stick mag, but could take full Gen 8 stanags and P-mags. I fitted an XT30 connector recessed into the receiver at the back and ran a 3S lipo in a pouch mounted on a sling with the battery wires run through the inside of the cordura terminating in an XT30 connector at the sling mount. Don’t have any photos of it sling and wired unfortunately.

It was good fun, 280FPS, woefully inaccurate with a 3" inner barrel, but had select fire, mag prime, etc… you had to look pretty hard to see the wiring too… but this was back on the day when options for this kind of thing weren’t what they are now… like this one… ![]()

Ended up in the bin eventually, and definitely more a case of “can I?” than “should I?”

Bloody awesome bit of experimenting and thinking outside of the box ![]()

Tried the gorilla glue for the 3rd time and seems to be holding so far, after assembling the blaster and running a mag through it, only feeding issues I had were from oversized gels cause it wouldn’t shot then 2 would pop out, i did have a bottle of overgrown gels so I must of grabbed that by mistake.

After 8 days down in the non-blaster zone of Victoria I was itching to do something, ANYTHING, to a blaster…

Camo livery on the stock of my M24 seemed like a good idea…

Built a replacement but I’m running out of A1 Gen 8 usable shells. Gen 8 gearbox, metal gears, chihai red motor and M100 spring = 325fps. Easy 35m but too wide a spread on 5 round burst

Do you need more Gen8 Gearbox shells?

If so, could possibly do a deal ![]()

Need more A1 AUG shells. After a while the screw bosses crack and have to throw them away

Sorry can’t help with any of that modern stuff ![]()

![]()

![]()

The cyma marine junker I posted a bit back about has been almost restored… just a few bits to finish it… need a bolt release as it’s triggering my it’s not finished OCD, and the stock may or may not change and it’s kind of a place holder, though tbh I like it more than I thought I would. Also have a different sight coming from China so should have that by 2025.

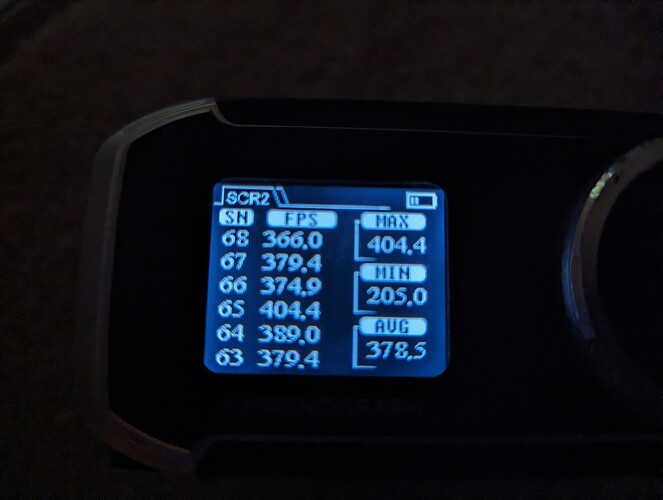

Running the cyma metal box, 13:1 gears, with ldt nozzle and tpiece and a 3d printed terminal piece so it can run gen8/SLR mags. Average 380fps with an m100, that I suspect is an m110 (not the first time I’ve seen that) and a neat 26rps.

Also has a t238 basic 1.9 trigger unit, it works well.

And the 203 just fits so well and solid it it. Pretty happy with it.

Another 2nd hand bargain that had a failed sector gear I got for a good deal… double bell ak.

Gave it the full treatment inside with SHS bushes, gears, piston and head, full cylinder and a better motor with an m100

I was hoping to keep power respectable… hitting 360-370fps and 22rps.

I have put these springs in other blasters and they are m100, but longer barrel with good seals just keeps pushing over the springs rating. Blessing and a curse.

Prick of a gearbox to shim. Spur gear has a 0.1mm shim, sector has a single 0.2mm shim, and 0.4 on the bevel… very tight box, had to ditch the stock bearings and go through two gearsets to find a spur that would fit with a 0.1mm shim to keep it running on the bevel gears bush.

This is my second double bell ak. While not as impressed after finding that in the gearbox for ease of upgrade… Still happy with them and have my eye on a couple more if I come across a deal on them

I’ve got a similar briefcase arrangement for my MP5… not the K variant though.

Got so many different handguards and stocks for it I need a bigger case.

When we were in HK we had the Queen come to visit at ShaTin racecourse. After she left a whole bunch of gweillo in suits emerged from the stands carrying small black hard briefcases. They would have really blended in to the local HK crowd

I remember seeing an old black and white Archive film about these being marketed to the US secret services back in the late 50’s……. but I can’t remember what gun they had fitted inside and they were actually chained to the wearers wrist!

Interesting video from my favourite YouTube dude, but still looking for the old archive footage of the original 1950’s design ![]()

Hey mate, sorry for the delayed reply, but I got sidetracked and forgot to let you know about a method to repair your shells and not just throw them away!

If they are made of proper black Nylon, like 90% of blasters out there, then there’s an old bush mechanic trick that you can use to repair them virtually forever ![]()

Get yourself one of those little pen sized Butane Gas Blowtorches and a packet of black cable ties.

Use degreaser/white spirits to thoroughly clean the area around and inside the broken screw bosses and blow out with air/aerosol electronic cleaner.

Fire up your little fire torch and use a cable tie as you would solder on a soldering job.

Heat up the cable tie just enough to melt and apply molten droplets into/onto/surrounding the screw boss until it’s completely filled and built back up to shape.

Once done, leave to cool/harden, then can be cut/filed down to appropriate height with a flat top surface.

Can then either use the correct size little drill bit to add the new self tapping screw hole by eyechrometor, or dummy assemble the receiver halves to mark out a perfect centring hole to disassemble and complete drilling to the correct depth.

Now you have a perfectly new and strong repair that will last a long time, and is easily repeatable at any time in the future if the screw bosses crack/strip out again…… not to mention many more Nylon blaster parts that can be repaired/modified/jointed/filled/reshaped/restored using this same method……. even with white electrical cable ties instead of the black ones if you have white nylon gears/pistons/gearboxes/external parts that need repairing ![]()

FYI…… Cable ties are pure black Nylon, they can be used to “plastic weld” repair many different types of various things around the house/garage that are made of Nylon.

My Electrician father taught me this back in the late 70’s when he had to repair a few car batteries that were split/damaged when fan belts had let go and hit the battery casings.

I also have used this technique on modern plastic/aluminium radiators that have cracked hose outlets and other fittings.

Can also use a soldering iron or cigarette lighter if you are out in the bush/shed and don’t have access to a butane torch! ![]()

More helpful shite I forgot to mention….

Heat Set threaded Brass Inserts!

I adapted/fitted these to many blaster builds, cheap as chips to order bulk online and only need a soldering iron and a few seconds to fit each insert by simply heating and then pushing into each existing screw hole.

Permanent, strong clamping force, fine threaded brass and screws for long life strength and no more stripped out self tapping screws or cracked bosses ![]()

A good detailed article here, which explains everything a bit better than my own efforts of simply buying these and jamming them into everything I used to work on ![]()

Some brilliant advice there DocBob

Bush mechanic’s have kept outback Australia going for year’s.

Most modern kids wouldn’t know how to fit a toilet roll.

Let alone plastic weld with a cable tie ![]()