Hey all thought I would start up a topic specific to the double bell AK range. Having now modified mine, there are a few tips I wanted to share as well as highlight a couple of issues I encountered and how I overcame them. Hopefully this helps a few of you if you have plans on modifying this blaster yourselves.

The version I have is the AK023 as pictured below

To start, my main reason for modifying this blaster was the challenge of modifying something other than an M4 style blaster, which I had done before. I wasn’t after super high fps or rof just something reliable. I actually was aiming for a drop in fps so it would be field legal and the real steel doesn’t have a high rof either.

Stock specs were 17rps on 11.1v and an average of 360fps before I changed anything.

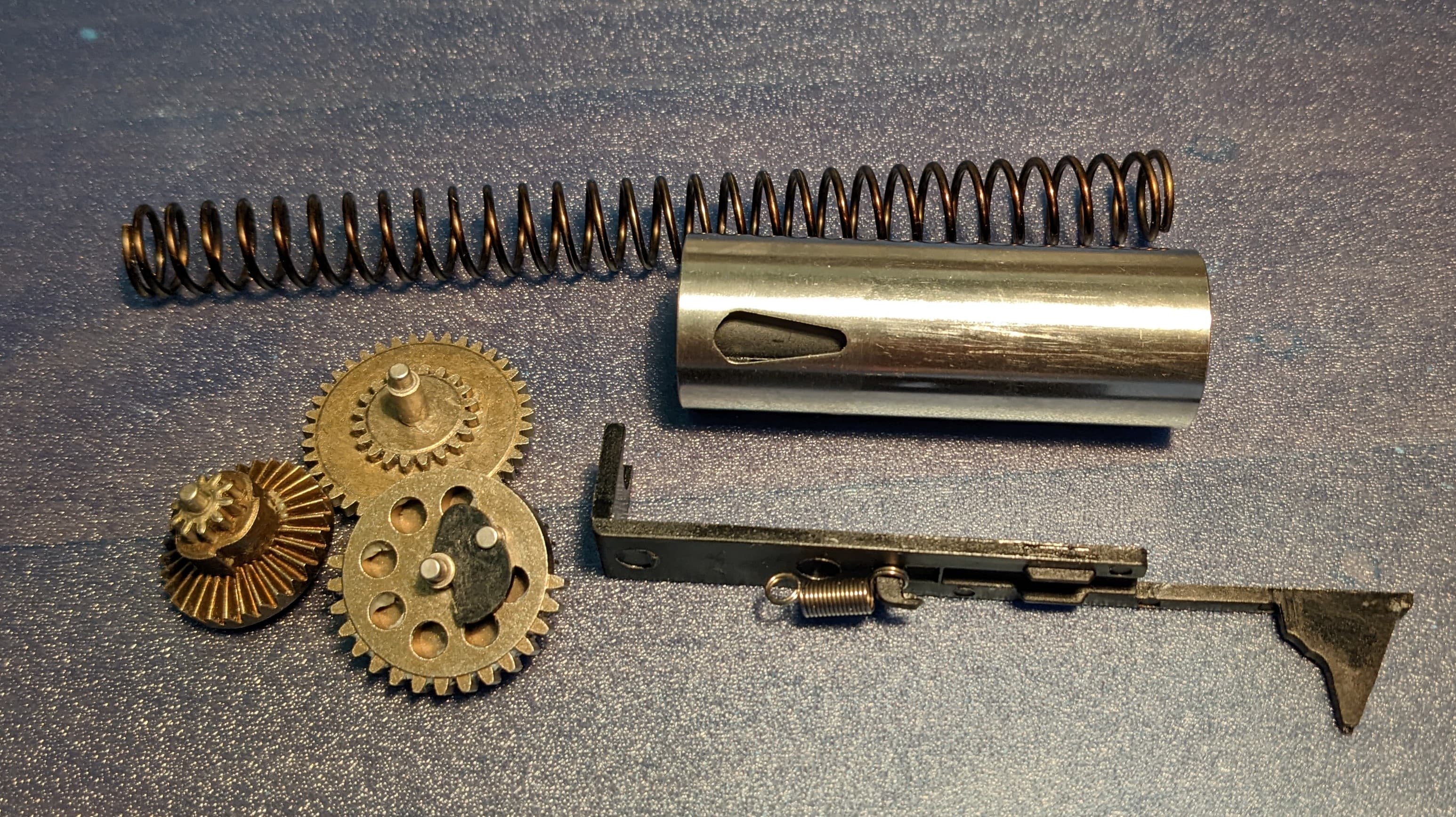

Stock internal parts of note are:

- V3 cast metal gearbox (not radiused)

- 18:1 gears with a very large delay chip on the sector gear

- 70% ported (port starting at 49mm) stainless cylinder

- 45cm inner barrel with 7.3mmID and 8.5mmOD

- 1.4mm main spring

Having taken apart the blaster there were a couple of issues I found straight away.

- The ported cylinder was under-volumed for a 45cm 7.3mmID barrel (ve was 1.13 using the gbf volumetric calculator)

- There was an air leak between the nozzle and t piece; and

- A vacuum was being pulled as the piston was being pulled back.

The ve could be improved to 1.66 with a 100% cylinder and the vacuum issue was due to an oversized o-ring on the piston head which could be easily fixed by replacing it.

I don’t have a pic of of the stock o-ring (I threw it out) but it pretty much filled the gap in the piston head and was not loose as they should be.

The air leak between the nozzle and t piece required an o-ring to be added to extend the nozzle by 0.5mm and get a good seal. The original nozzle was stuck on pretty good so I cut it off, but seeing as these blasters use the same nozzle as a jm gen 8 it was easy to get a replacement.

Having thought I had sorted out all the kinks I then started upgrading the internal components and this is when I came up against some more issues.

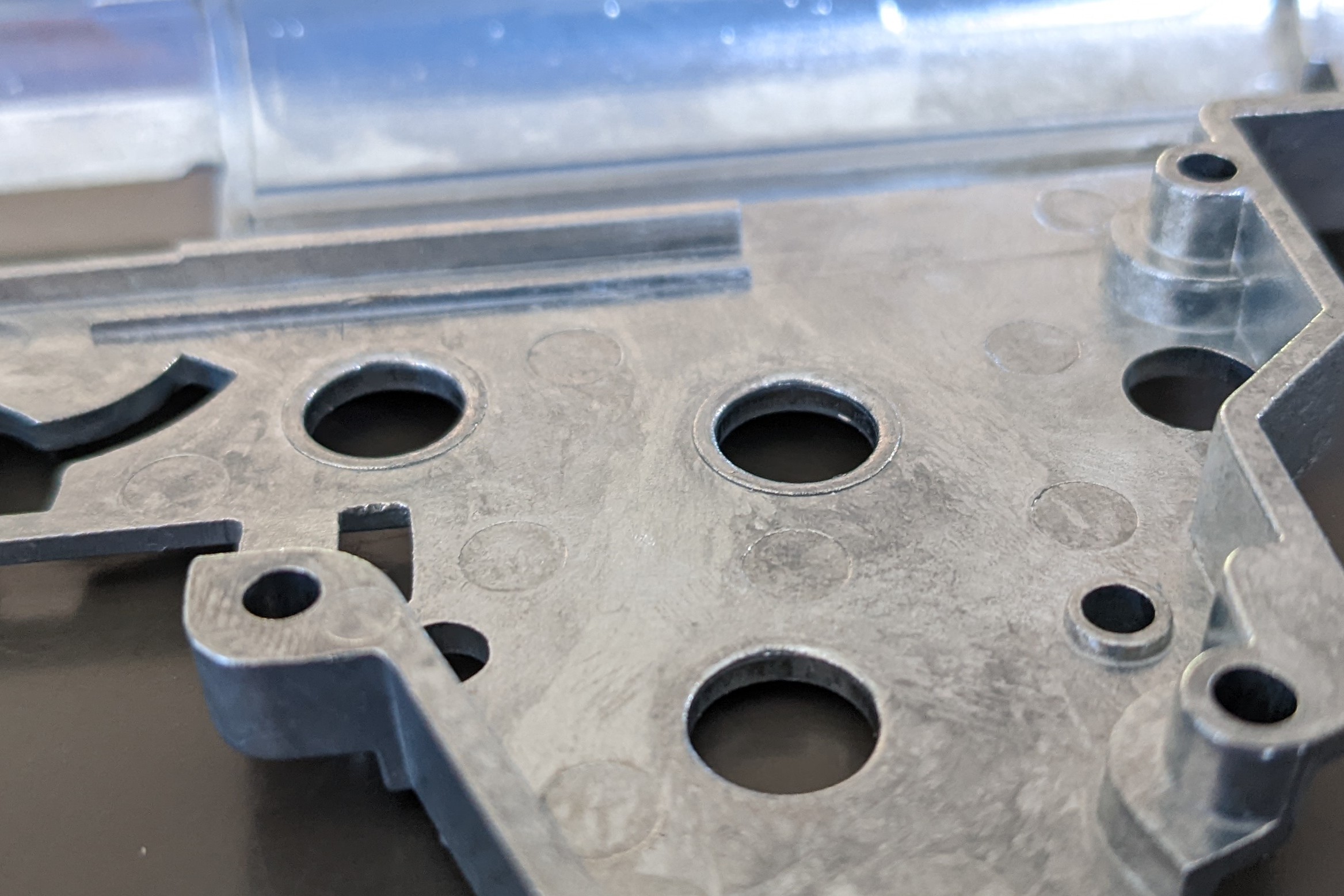

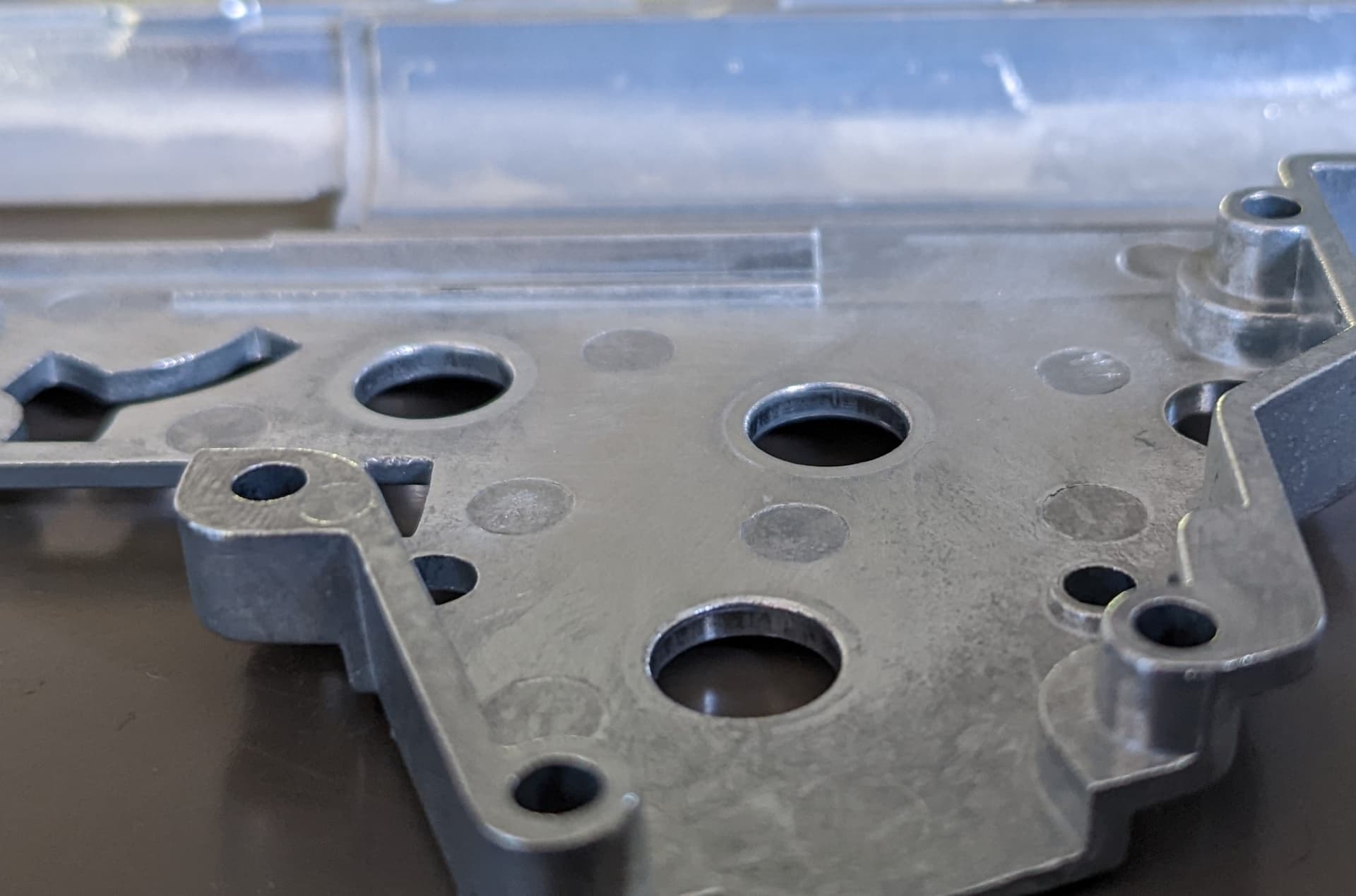

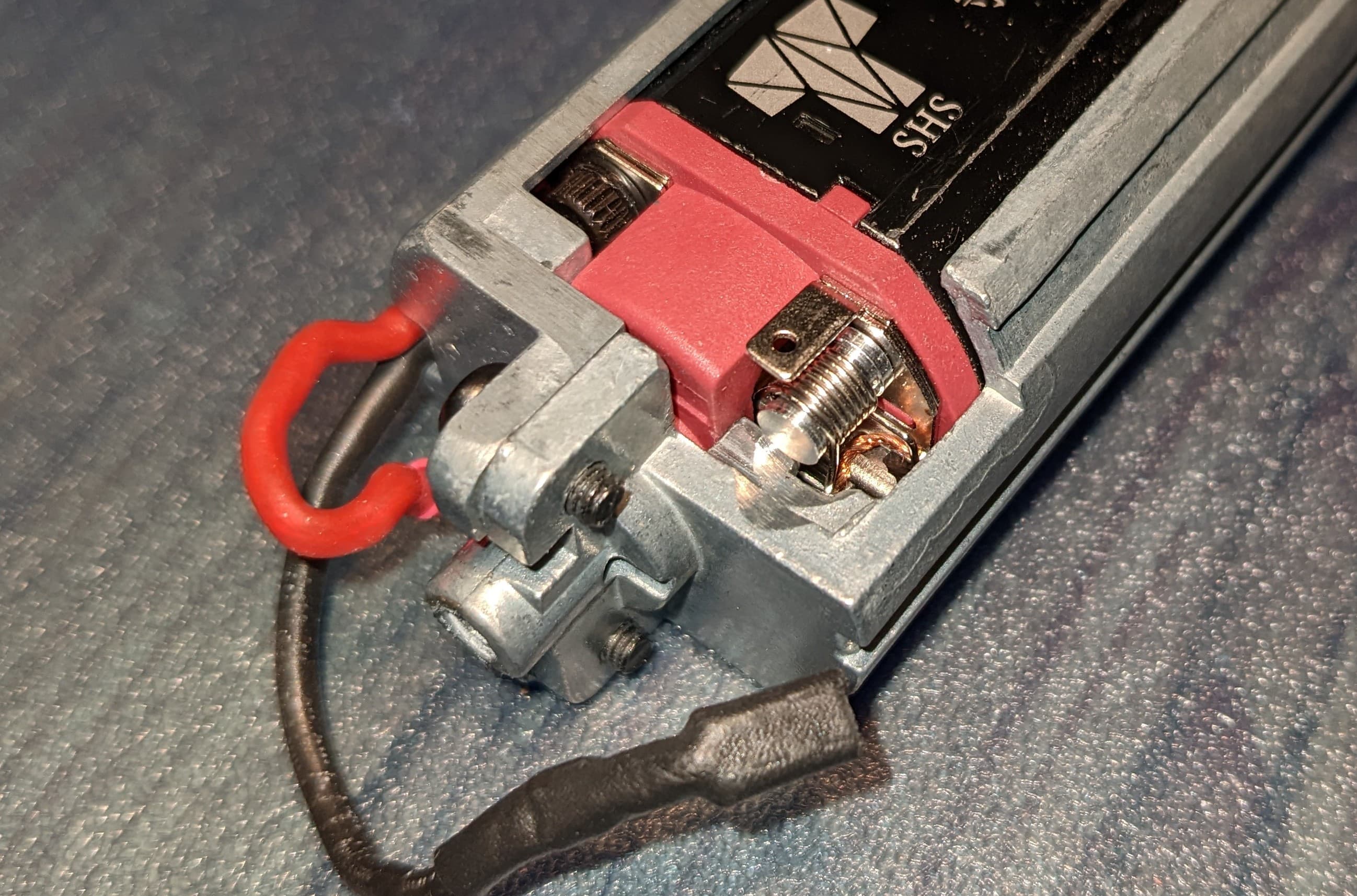

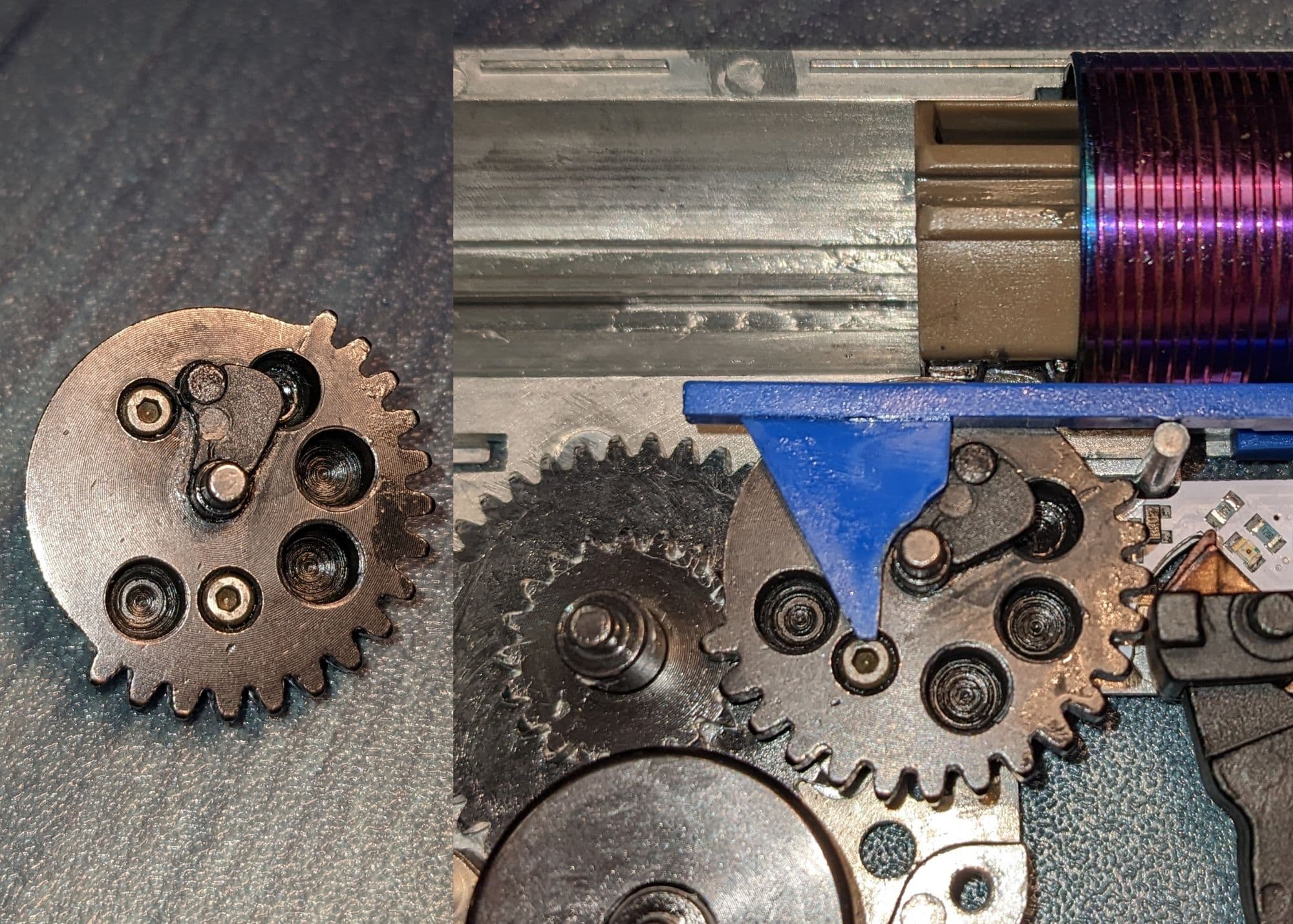

- Both the SHS and bigrrr gears I tried were too tight to shim when the gearbox was closed. From inspection this was due to there being no recess for the bearing lip to sit in and there was actually a raised area around the holes for the bearings which caused them to sit too far into the gearbox (see below image).

I ended up sanding the raised part down and replacing the stock bearings with retroarms bushes, which allowed for enough room to properly shim the gears.

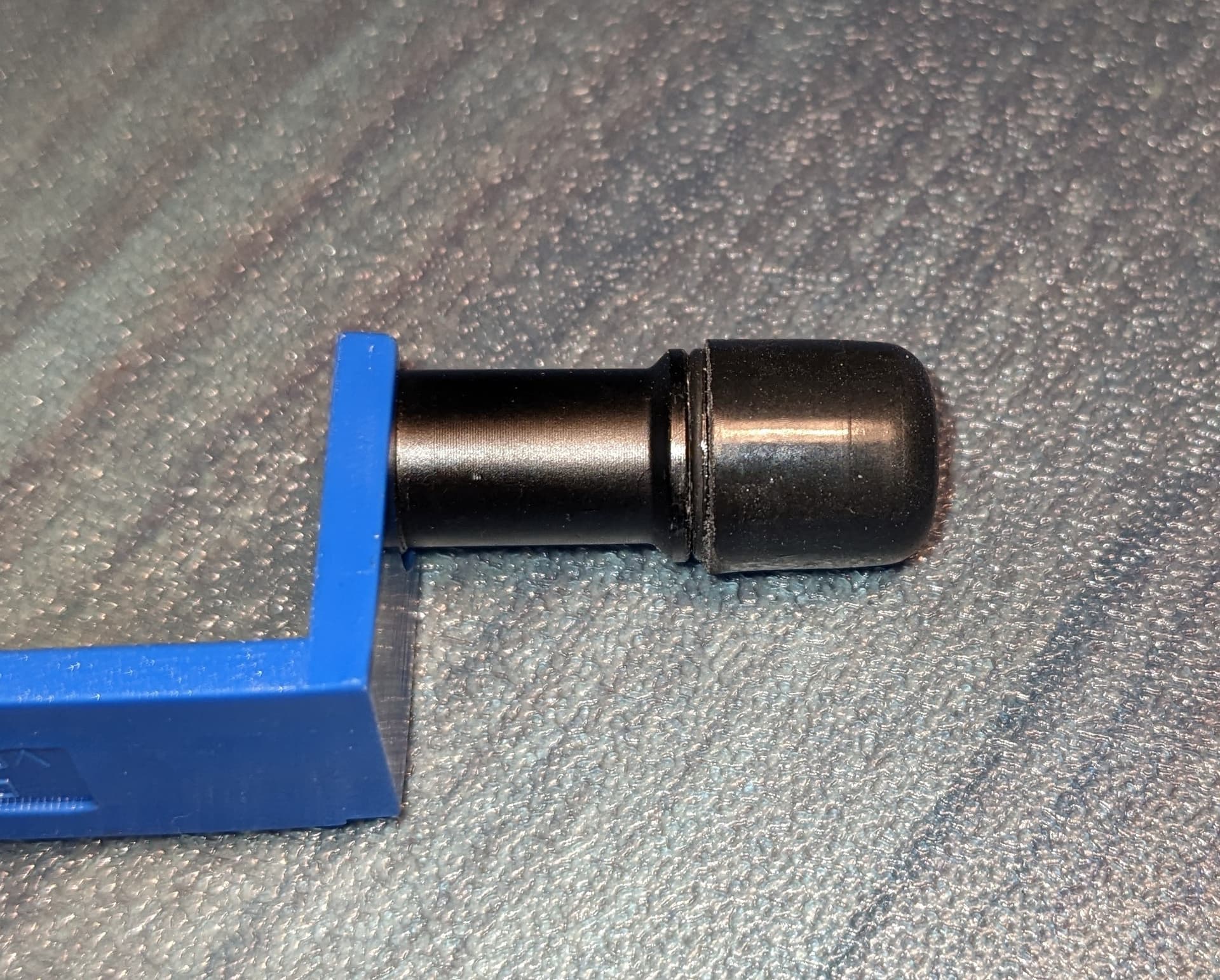

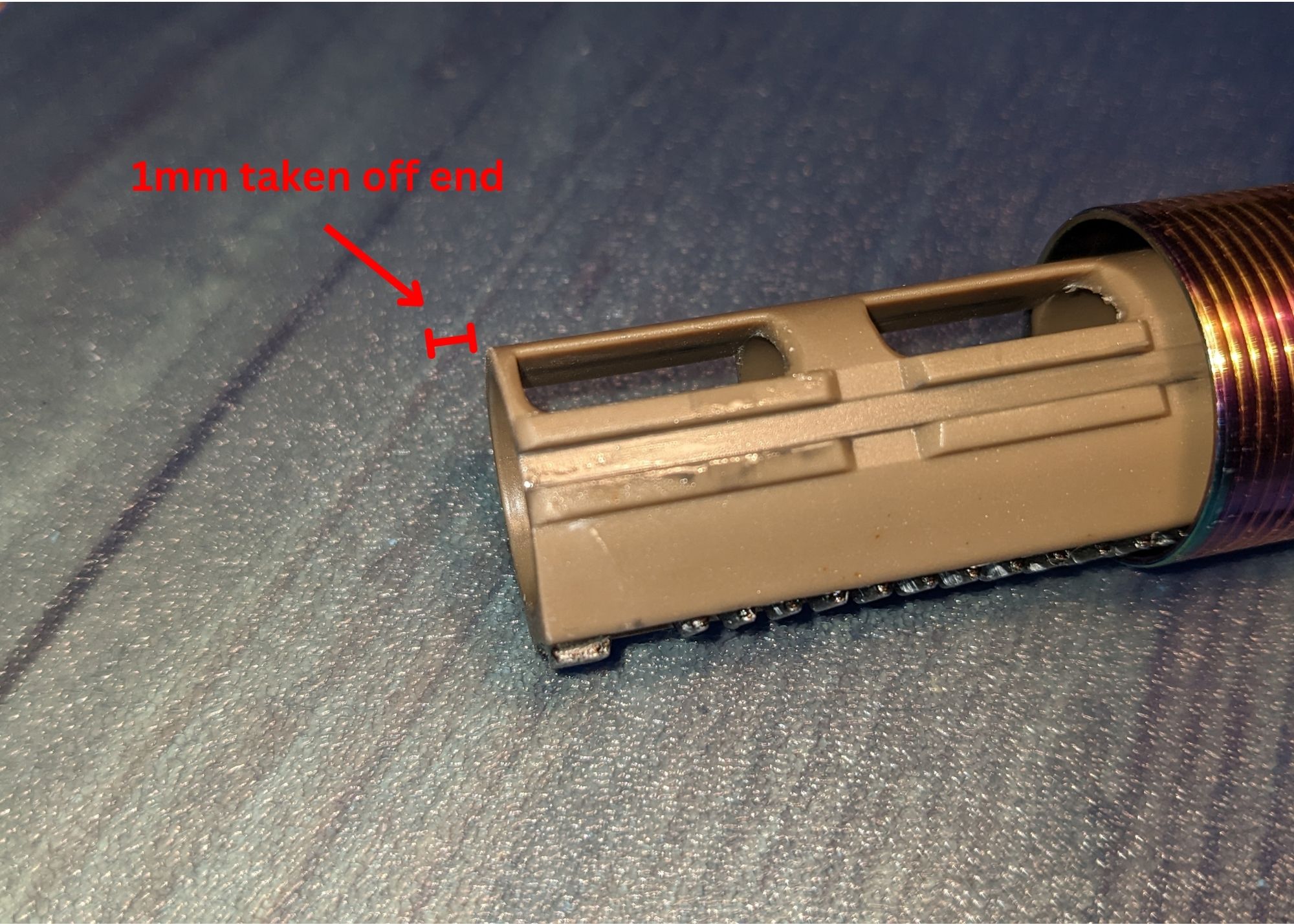

The stock bearings also seemed to not spin very freely, so I suspect they needed replacing anyway. - The piston I originally tried (modify) was binding and not moving freely (noticed that the stock piston was also doing this, but only just). After trying several different pistons I settled on the aztech piston being the best fit however I did take 1mm off the back of it to clear the back of the box/ spring retainer before the piston gets released.

- I also noticed some casting issues in the gearbox. I.e there were some bumps in the piston rails and guides for the tappet that I sanded down smooth using some 600 grit sandpaper

- The motor cage was contacting the springs for the motor brushes and would have shorted. I fixed this by grinding out the area that was contacting with a file

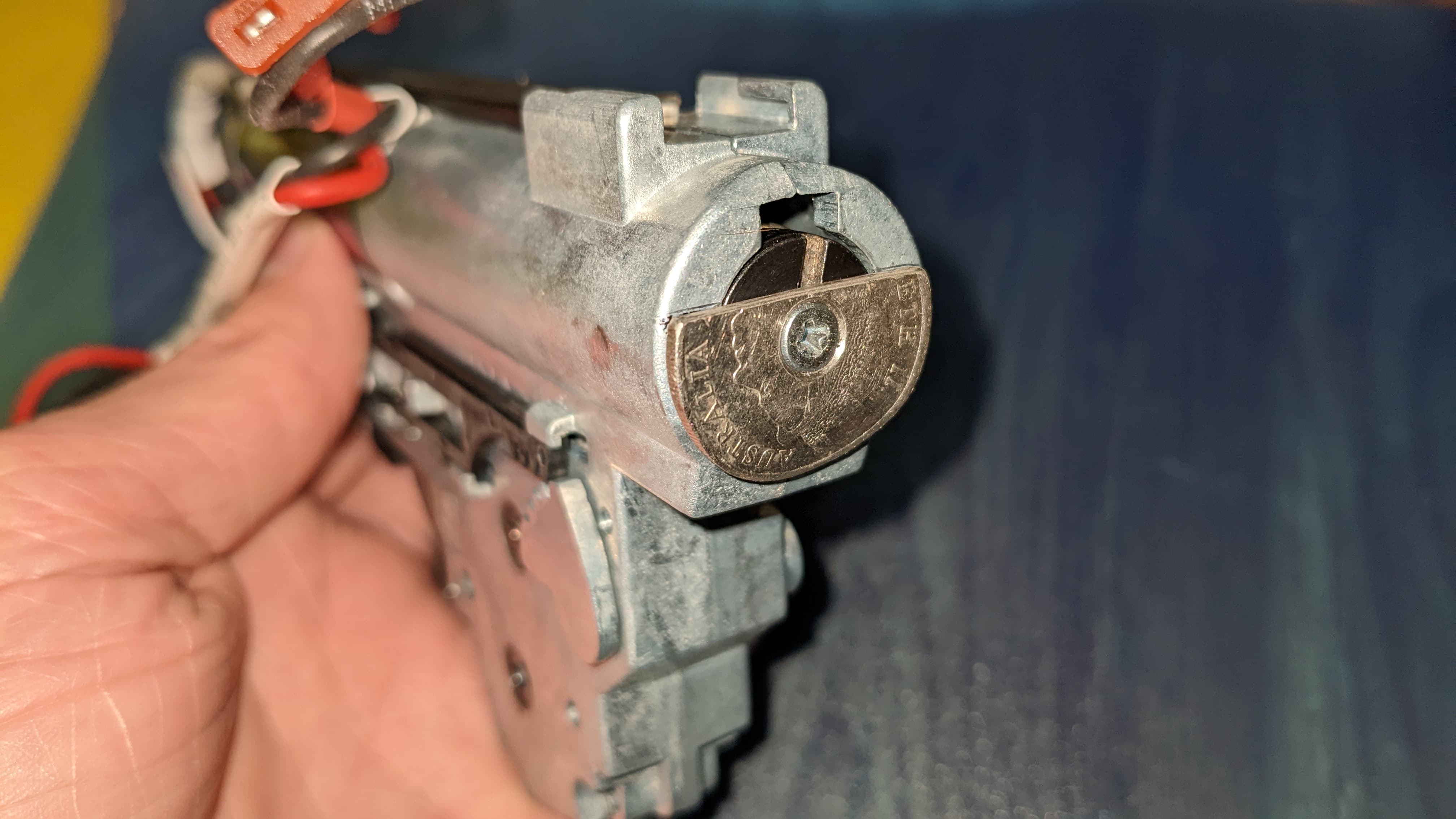

- The spring retainer was a bit wobbly with the new spring too. To fix this I just used a 10c coin and M3 countersunk screw to secure it against the back of the box. I did have to Dremel out a small amount of material from inside the receiver to make this fit.

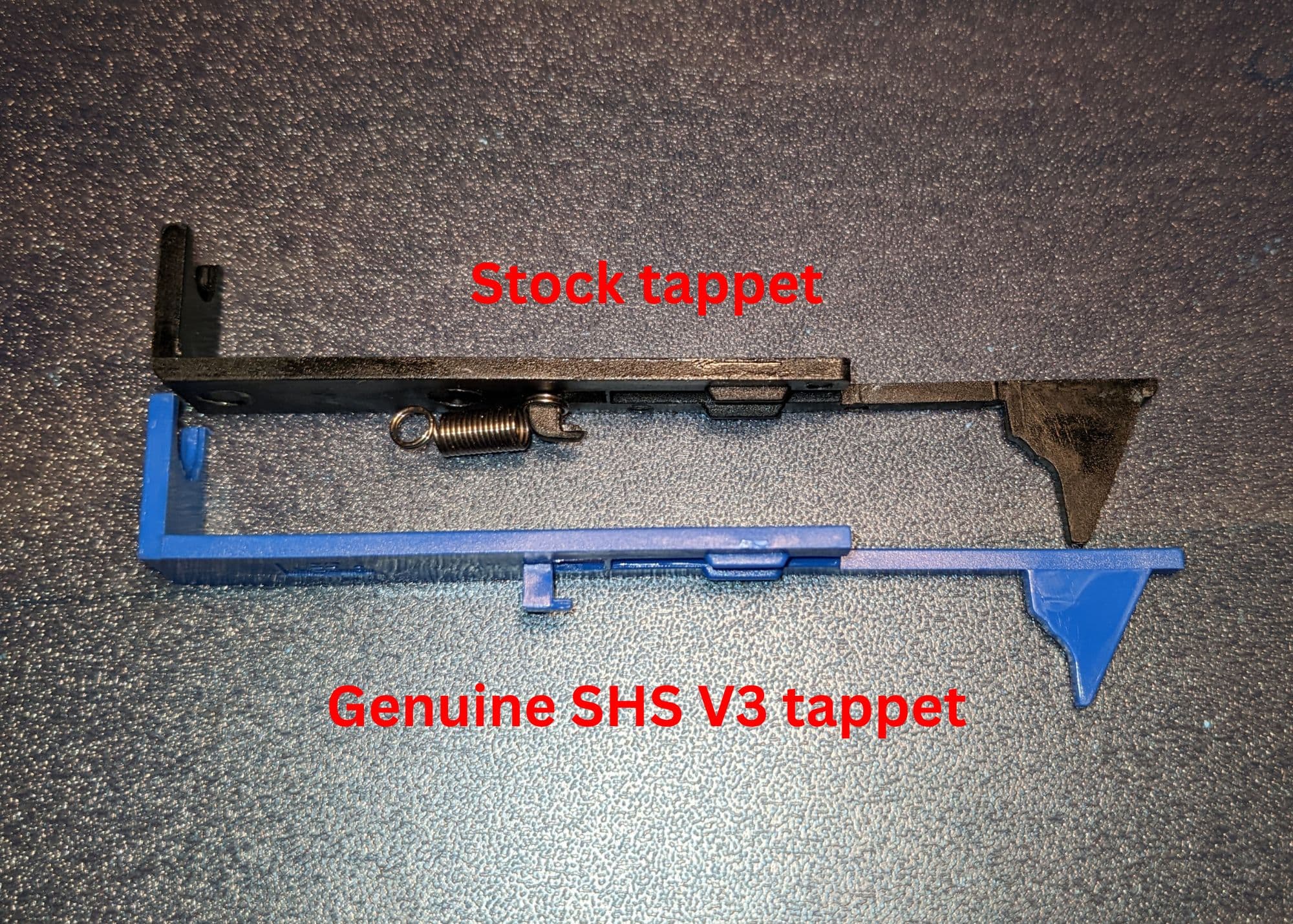

After all this I put the blaster back together however I then was experiencing some timing issues… Originally I had used the stock tappet plate + the SHS delay chip and was getting a drop in fps on auto. I then removed the delay chip and had no fps drop but was having feeding issues. Finally changed to the SHS tappet plate, trimmed the delay chip and it started to work great. Consistent feeding and no fps drop on auto. The SHS tappet profile is almost identical to the stock one though so I am sure it would also work.

I will point out though that I could not find Genuine SHS V3 tappet plates in Aus so I ended up getting one from Redwolf. The ones I bought in Aus had incorrect markings and did not fit a standard nozzle so be on the lookout for these.

Final Parts used:

- Stock V3 gearbox (radiused)

- Stock cylinder head

- Stock nozzle (with o-ring added to extend nozzle)

- Perun V3 optical mosfet - CQ Blasters

- SHS 18:1 gears - Azraels

- SHS delay chip (trimmed) - Azraels

- Generic 100% rainbow cylinder - Armoured heaven

- SHS high torque short 480 motor - Azraels

- SHS V3 tappet plate - Redwolf

- Modify V2/V3 AR latch - AH Tactical

- Retroarms 8mm low profile bushes - CEH

- JM gen 8 nozzle - CEH

- Aztech piston + piston head - Azraels

- SHS V3 return spring - Redwolf

- ASG M95 spring - Ausgel

Post modification I am now getting 20rps and an average of 330fps with a nice snappy trigger.

I did also make one external modification which was filling down the mag release to accept the fakelight Rx mags.

Overall I am very happy with the build now it is complete, but it certainly wasn’t the straight forward build I was expecting. In saying that I learnt a heap doing it so it was definitely worthwhile.

Interested to hear if anyone else has experienced these issues too.