haha I know that measurement.

I noticed that it’s backwards to previous like the JM ACR etc. Hmm might have to pass on this one unless some wizz like Dchapo can 3D print them. Because I need spares as I push them.

haha I know that measurement.

I noticed that it’s backwards to previous like the JM ACR etc. Hmm might have to pass on this one unless some wizz like Dchapo can 3D print them. Because I need spares as I push them.

Haven’t touched it for over a week. Probably be another week before I can get to it

I potentially could, but I’d need to get my hands on one too get measurements naturally.

I’ve successfully printed t-pieces for other projects, and I see now Aztec are selling printed parts now too.

I’d suggest anyone who has one of these tears the SOB down and has a good look.

@Wombat the pinion is sitting on a D shaft but with no grub screw could well move away from the bevel gear.

Ah I remember those…

Wrong thread again ![]()

![]()

![]()

![]()

Well I won’t do that again just got zapped by a thunderbolt. Are you mother nature or something. Holy moly that was close. Unclipped my dog from the ceiling. Can’t hear a thing lol 20 drops of rain after, now nothing.

Big baddaboom.

Spoke to iHobby and they are good to replace. I will drop down this week. I also need to get my new one out and give it a lashing to make sure functional! Forgot about that one already

show them this thread, and the pics of the opened up blaster…

Ask them, how many they have had returned so far…

be interesting to see what they say…

lol … maybe … after they swap it ![]()

You dont have to do it in an aggressive way…

You can gather info, just by a polite conversational tone…

" Have you had many others with the same problem…?

There was one with a gear that nearly collapsed…have you seen the photo?"

without being rude, you can make enquiries, and get a gist of whats happening…

Maybe it was a couple of slack employees at the factory, maybe they all came out like this…?

True that, jumping up and down getting angry gets you no where. Have patience and politeness can usually get the other to motivate and help you out.

Sometimes shit happens and someone’s having a bad hair day. Especially these days with the touchy feely type can’t handle a bit of constructive criticism. Just the way it is.

As has been pointed out before the mag catch placement’s a little off with these too.

Just to be sure I wanted to wait until I received my spare mag from iHobby before passing judgement… can confirm it’s still shite with the new mag.

There’a no positive click when the catch engages, feels very wishy washy compared to the LDT. The cutout on the side of the mag is moulded too low for the metal catch to clear it cleanly, and the cutout can’t be altered without compromising the structure of the mag shell… ask me how I know. Thank God for Superglue ![]()

The catch itself can’t be easily altered either due to way it’s been diecast.

To get around it you almost have to perform a bit of an AK rock when the mag’s in… it bottoms out in the magwell and pulling the mag rearward allows the catch to clear and engage in the cutout.

Pretty rough and ready assembly. Just shove in the gears and see where the bushes end up

Installing 200mm Ausgel barrel when the glue sets on the t-piece. 1,18 spring

Fkn ell sorry but more characters

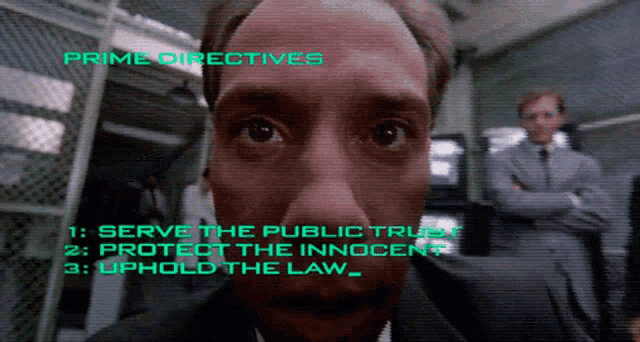

Sounds familiar. ![]()

JM didn’t put a lot of effort into the assembly, that’s for sure.

Original t piece or did you find a newie? ![]() I’m after a second t piece so I can swap between long and short inner barrels and run a suppressor.

I’m after a second t piece so I can swap between long and short inner barrels and run a suppressor.

Don’t know.

M4A1 , circa 2017/2018.

I think it has a gen 8 in it.

Sounds like a Gorky kit… they were the shizznit back in the day if you wanted to go MP5. ![]()

Gen 8 in it? No wonder it’s getting such high FPS. ![]()

Running existing t-piece. Removed the sleeve from the barrel using the old hot water trick and glued it in place so that the barrel would not rotate when installed. Had to use superglue