Looking forward to see it in action.

It… Has… fed gels!!

Got all together, and just quickly put a couple gels through to test and it shot. Bit early to test any further so keen to get home and try it this afternoon!

There is very little to be able to tell what it has under the hood, apart from the 6 screws in the lower receiver are now stainless, and if the dust cover is open you can see that CNC beauty.

Also if you look up the mag well it’s pretty obvious.

All went together really well, or at least as well as a vector does, felt the same really.

The weight feels awesome, not overly heafty but definitely heavier than our other vector which is almost identical externals and metal gears etc

One thing well worth noting, it feels really solid. No creaking and flexing at all. Awesome.

Hopefully it tests well this afternoon!

It’s alive and works!

Results are on m110 short 4 teeth.

Drum doesn’t quite keep up on full auto, best it can register is 25rps, but it is skipping the odd gel so is a little quicker. I’ll sort that out next.

Currently just over the moon it works and works well… sort the double drum out and then let the poor thing run through the ringer at a game.

Ooo more juicy bunfighting between WAT and RPM ![]()

Will it ever end? ![]()

![]()

Props to Rowan for dismissing it as trash talk. One side of the industry/hobby I can’t participate in is infighting. We are a niche sport/hobby and should work together… anyway.

I have opened mine up again, removed the little sector gear anti reverse as it was stiff, and rubbing gears a bit. Does stuff all anyway if the normal anti reverse works. Also changed the tappet plate, might have cut it a bit short.

Now sitting at 27-28rps with a 5-6 round burst. After that the mag doesn’t keep up. On the hunt for high speed mag motors again! The double drum has a step down gear much like gen9 style mags do, so not really surprised it is struggling once it is in full swing.

For now, I have semi, 3 round burst, and auto is a 6 round burst as the drum seems to keep up with that, likely as the mag spins for a bit after and “pressurises” the feed tube. Pure speculation.

I for one, am VERY keen to see what Rowan does with one. He is the original lord of vector. 30k infinity motor with dsg(9:1) will be a fair bit quicker than my 30k Chi Hai ndfeb motor with 13:1 gears.

Righto, been a while, been sick and busy but have an update on my feeding issues.

Tried some hi speed mag motors in the drum, 4 different types. The three faster ones required a little shaving to fit. which means to go back to normal, or normal “hi speed” motors (not the red, blue, gold ones) the motor now needs some extra girth/shimming to sit properly. Annoying, as the original vector which “only” does 24 rps, worked fine with the normal high speed motors.

Ordered another double drum, one for each it will be.

Still having issues, but I reckon I have tracked it to… seems to be the T238 trigger unit not supplying enough power to run the higher speed motors. When the coloured motors are in, depending on the speed motor, will either barely run them, or not at all. I then put in a normal stick mag and it ran “fine”. Tested it on 11v in the blaster, then manually tested it straight to a 11v battery. Night and day difference! Actually on 11v in the blaster, it sounds like a 7v wired straight to the mag!

So this weekend on “why won’t this c%*^ work?”… I will be wiring the mag terminals straight from the motor and battery wires, installing an old fashioned diode with charging handle switch for manual mag prime.

Yes, I will lose auto mag prime, but as long as it works similar to the original setup I will still be happy. The hold up is that Jaycar is closed by the time I get there after work most days. One day in the week left to chance traffic and finish on time, or I will just go in on Saturday.

Even more frustrating, I know a have some 10amp schotky diodes somewhere… can’t find them in all my parts boxes, tubs, and cupboards!

So hopefully, this weekend I will have my almost 30rps vector running as intended!

Bit of a rewire it I works! 27rps feeding well! Perfect as a bit over that needs regular maintenance, and vectors are not something you want to be opening too often.

Only needed to be rewired the mag terminals to come straight from positive battery wire and negative motor wire… also ran a wire so mag prime still works via the charging handle. No auto mag prime from the t238 but I’ll take working over that any day.

Going to give it a run at Donnybrook today and see how it goes.

It has been a long journey! I’m not ready to do the other vector yet but in time I reckon I’ll have at it, hopefully get some proper fun out of it today before releasing it to the real test… In the hands of the wife!

that is…Roksolid. Thanks 4 sharing

Right so after owning a vector for 6 years, and I have never used one on a field as the wife always uses it… I also didn’t want to wear out her baby and have to work on it.

Used this one for most of the day out and had a blast. Next time when the wife uses it will really test it out though but for now I am glad the journey and build is over!

Two thumbs up from me.

Got the next build candidate lined up? ![]()

Good Job.

First time is the hardest, and longest.

Next time, you’ll do it soo much quicker…

Get hold of another, do it all again, so you have a spare…!!

![]()

![]()

Kidding, …Not Kidding…!!

@Friendly_Fire I have a mate interested in one, but given the expense will have to judge the level of commitment, not a cheap build!

TBH, I am considering doing the original vector in the collection. Happy to wait til it fails though, not in a rush to do it again.

@BME sure is. I at least know the limitations of the T238 vector mosfet now and a workaround, also a number of other annoying little things that just meant pulling it apart to change a thing and put it back together and test… and repeat.

Because it is a vector, it is just a much longer build time than well, anything else. It is less quirky to work on than the polycarbonate stock box, but still has it’s quirks. Like you probably still have to shorten a short motor, still need to shorten an anti reverse latch so it doesn’t contact the pinion gear. Still have to trim the angle out of the back of the piston, and still have to ensure you have the cylinder head aligned to get an air seal.

It is done now and I am glad it is, and the results are good. I could look into a better slightly faster motor, but tbh it is quick enough, and in the double drum normal hi speed motors only just keep up. My other double drum with the nonsense fast mag motors is currently too fast, just throwing balls around the mag and not sucking them in, so will be adding a variable resistor to tune that in the coming weeks. If I can nail that, might go for a faster motor ![]()

When did you start doing this sort of stuff… asking for a friend ![]()

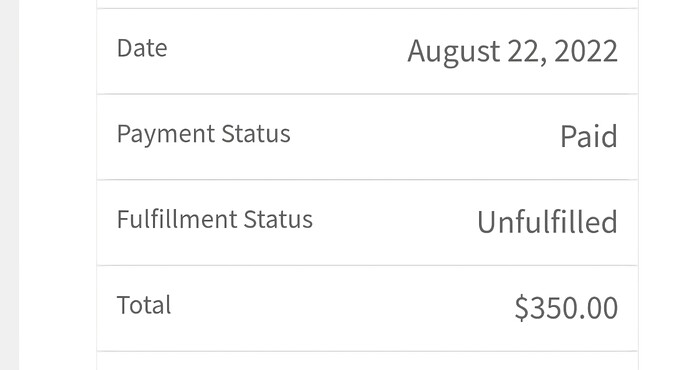

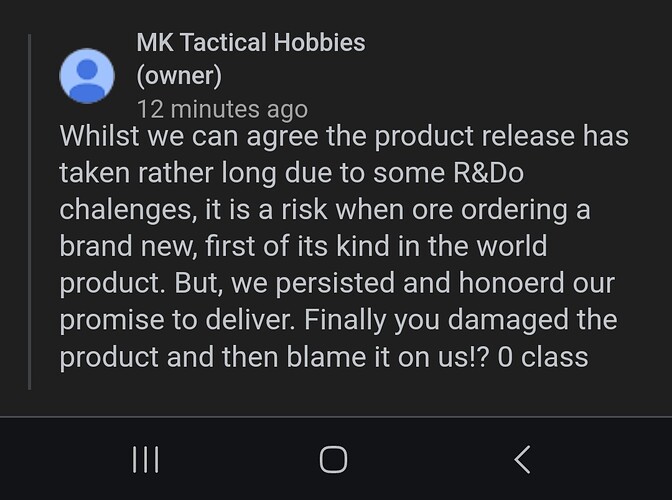

When did you pre-order your gearbox? I ordered mine back in August 2022 and have yet to receive it yet. Have sent emails in May, when Mk posted on facebook they were finally in production and I was assured it was coming. Now July and I’ve resent emails chasing up and now no response. Pretty dissapointed seeing people and stores get theirs whilst I’m still waiting. My fault for pre ordering gel blaster stuff. Wondering about the possibilities of chasing a refund at this point lol

I was the first to pre order… but also had given some advice and design cues into the gearbox itself…

Have you tried messaging MK Tactical Facebook page? He is usually pretty responsive, but it is a side gig for him so have a little patience, and I understand you have been waiting.

All the best and will be great to see another vector with an mk box.

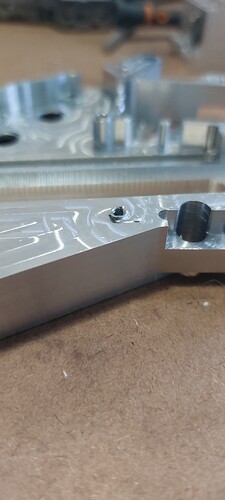

Finally recieved today, a little unhappy with some of the machining but we’ll see if it comes together without too much fuss

Yeah thats a little sub standard, looks like a few bits on the machine are a bit worn or something?

All 6 of the MK boxes I have are pretty good, on one there is a little bit of machining anomalies but were only cosmetic. Might be worth seeing if you can get a swap over or something.