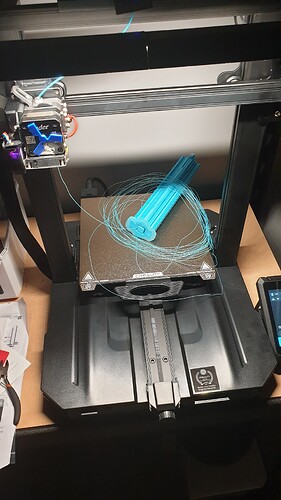

Is that infill or support material in the middle of it?

Support, top bridges to much to run without any.

Ahh, thought it was infill and was curious why you’d choose the zigzag one.

Nah its support and zig zag helps cut filament use normaly, depending on application tho i change around what i use to find the best between time and material used.

Yeah, I pretty much only use zigzag supports, but I’ll orientate the part to get the support direction how I want it sit.

I do notice that even with the setting being the same for both my Aquila and Ender 5 for supports, the Aquila comes out out a lot cleaner on the supported faces, like the Ender had a lot more drooping or loose lines, but if I reduce the distance and roof sizing it just fuses to the print.

Well its done but gotta run out so will get pics when im home, so far its looking decent tho despite some weirdness with supports at one point.

So i got tired and just really didnt have energy yesterday thanks to the heat so here is a janky phone pic of it, came out nice tho.

Another kit I found, just the shell ATM but takes a V2, just gotta print the rear pad for the stock and reprint a couple parts for fitment.

The kit comes with a threaded buffer tube for the rear but made a pic rail version for the folding stock of another kit

Had printed the handguard in a silk filament cause I thought it would look nice but forgot the base supports in Prusa slicer are retarded and it had too much flex for my liking, will probably paint this one some not so default colours.

That looks awesome, great work ![]()

Looks nice, what kit is it?

Think it was called “Day Breaker” on thingyverse.

And the stock was EXO or something.

98% on what had been a 21hr print…

After having a closer look it turns out the gantry had was at max height, which was a surprise to me cause the slicer should of notified me if it was too high.

Will have to measure tomorrow but it’s supposed to be 270 high and the part was about 240.

That’s a interesting part. Systems failure ![]()

Ever since eSun went to these cardboard spools almost every one has tangled and it’s never at the start of a print, always like half way or near the end so it wastes most of it.

It’s been giving me the absolute shits of late ![]()

Just do what i do, push the end back out and it doesnt waste anything, or you can respool the whole thing.

what do you mean by this? pushing the filament back just untangles it, which is what I have to do after it’s wasted the print anyway.

Really don’t want to be having to respool almost an entire kilo of filament just because they can’t roll them properly to begin with either.

The cardboard spools are visibly narrower and upon measuring both the cardboard is like 3mm narrower, which is going to cause the filament to be packed tighter width wise which seems to be what is causing th tangles, cause it’s usually on the sides that it does it.

Yea just push it back through, also its not just their cardboard spools ive found. has happened on a few of the old plastic ones.

Im going to start respooling mine when i bother to print out some reusable spool rings just so ive got them on hand so i dont have to deal with cardboard breaking down over time on the printer.

Time to work on that ar smg, will post final pics later and maybe the video timelapes because those are always interesting.

Also an update on the smg conversion, the top rails are done and join nicely to each other.

Just have to print out the: barrel nut, vertical grip, the barrel extension, sling point.

Man that mouse pad is cooked ![]()