It depends on how much work you are willing to put in for minor gains and risk of gearbox casing failure , or how much you want to spend to do what you want out of a fancy CNC box or other gearbox conversion.

Without any work, an m90 spring should get you 300fps, if it doesn’t use a bearing spring retainer and it will, usually that gets it a little over. The gearbox casing will fail and crack the front off in standard form after an unknown time. I have seen some do it standard form in the warranty period, and I have seen some last a couple years! Most though, maybe 6 months of regular outdoor play.

The issues with the standard metal box:

poor seal between cylinder and cylinder head

oring loses its seal after a bit of use

the hinged door pistol grip does not lend itself to good pinion to bevel alignment.

the motor tower has movement that also leads to poor pinion to bevel alignment.

factory shimming is… factory shimming.

I also, have a cqb and mrt.

My cqb has seen over 6 games outdoors with drum mag and no love running m100; with no cracks yet doing a comfortable 300fps.

The parts and work done to it though…

- Radiused gearbox. All eight corners of the cylinder opening. Spread the impact forces on the front of the gearbox over a greater area rather than focus them in a sharp corner.

- Added a rubber washer glued between cylinder head and stock cylinder head pad. Not so much for “AOE” but more for absorbing some of the impact force on the front of the gearbox.

- SHS piston with nylon SHS head, piston head ports bored out to 2.5mm. This was lighter than the piston assembly, has a good seal, and the nylon piston head is a bit less impact force into the front of the gearbox.

- 3d printed a spacer around the tpiece to fill the area between the gearbox front face and barrel adaptor, this is a bit of an experiment but I have used it on a blaster that the front was completely blown off, held on only by the tappet plate, and the blaster works as normal. I can not say if it prevents breaking the gearbox but it definitely will keep it running for a bit longer after it breaks. So far I am convinced it helps prevent it breaking, I have a few mates and random people testing this for me.

*Cylinder head sealed better to the cylinder. Using a couple wraps of gas fitting tape UNDER the cylinder head o-ring, then really tightly fitting the cylinder. The standard blue cylinder is gone for a stainless one, but that is more a personal preference. After a bit of use the standard blue cylinder will be shifting with the piston, it just isnt tight enough and will lose some airseal here.

The above is more about prevention, I doubt it is a cure though. The following is more for the performance I wanted

- 13:1 gears short stroked 4 teeth

- M100 spring with bearing spring retainer.

- Lower speed high torque motor, with a good bearing tower that has no movement on the shaft, with 13:1 gears it has similar rate or fire as standard.

- Replaced pistol grip with one that aligns the motor properly and doesn’t have a hinge door. A major issue with them standard is the pinion is not located solidly, and the shimming is shit. so they nearly all come back with a stuffed bevel and pinion. Replace the pistol grip and motor tower, good shimming with proper bevel to pinion alignment gets rid of that issue.

So far, it has worked, and performs slightly better than standard. I have gone up a spring and it now does 330fps, however yet to test at a game though has dumped a few drums in the garage and no sign of cracking yet. It has also been using with double drums by my wife who has no concern if it breaks, and I have told her to break it. She honestly is hammering it, and it seems to be surviving with no cracking yet, so far so good!

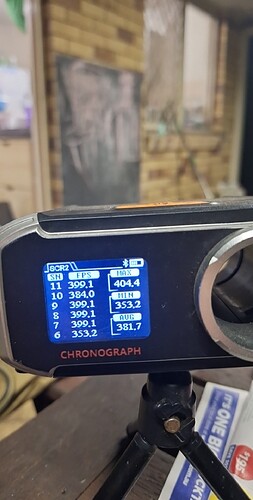

The MRT I got only a few weeks ago, It is setup the same but with a full stoke, 18:1 gears and a 45k ASG Infinity motor. Full cylinder, M100, bearing spring retainer, and the barrel is a 350mm 7.4mm i.d. Testing many mags in the garage and a load of dry firing it does a nasty 27rps and 370fps, which will likely drop to around 350fps once the new spring settles.

I will likely drop a tooth off the sector gear and trim the barrel down to about 310mm, just to pull a little power out of it to make it more field legal. However I am going to run it and see how it goes.

I am trying to break them, and trying to prevent them breaking for as long as possible. So far all this works well, the tpiece spacer is definitely the secret sauce though. I have a mate who has been running a cqb with one, and it was cracked almost completely on one side when I put it in over a year ago. It might be broken now and only held together by the spacer, normally without that it absolutely would be. He tells me is it still works fine so I can’t get it back on my bench to verify anything! That’s good right?

Anyway… I have fixed hundred of metal wells gearbox blasters, and it is always sad to see the gearbox broken, but even more when it is earlier than people hope and deserve. So I have always tried to do a few things to help it last longer. The catch is to do everything I have done to mine is a fair amount of parts and labour, so generally not worth it when you can just get a better blaster and be happy. If you own it already and can do your own work it is okay. They are decent performers as they come, and easy to work on so that helps, it is hard to not recommend just spending the extra on a more reliable blaster though.

Sorry for the monster post, I even tried to keep it short, but there is so much information worth sharing.