This is a bit of a guide for the teardown and possible upgrade to the latest ZY UZI gel blasters that everyone’s red hot on at the moment… big thanks to @RokSolid @Maiphut & @BME for providing the gel blaster… very much appreciated. ![]()

No review as such… BME’s pretty much covered that beautifully in another thread. This is more of a rough and ready guide for gearbox removal… if you’re game. ![]()

Initial Performance Stats

Put through the chrono in stock trim, this UZI’s hitting around the 135-140FPS mark… a little lower than expected and less than the chrono results on X-Force’s review, which was around 175FPS stock

The Teardown

A small Phillips screwdriver and a pin punch is all you’ll pretty much need… but be aware, there are quite a few small screws to remove ( 15, in fact! ) and keep track of and they’re not all interchangeable, so grouping of parts with relevant screws as they’re removed is highly recommended. Lots of photos to refer to on reassembly is also a good idea. ![]()

First things, remove the magazine and top cover, unscrew the front collar and remove the outer barrel, exposing the inner barrel.

Remove the large takedown pin located at the rear of the grip just behind the safety switch.

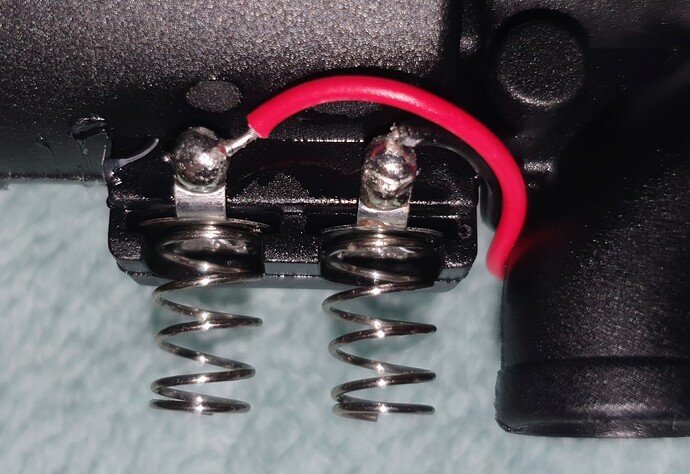

This allows the grip assembly to be removed. Unclip the two wiring connectors.

Next step is to remove the rear sight assembly. Remove the two screws on the back of the end plate.

Then punch out the small knurled pin located in the side of the rear sight.

One the pin is removed, you can access the spring which locks the rotating aperture sight into the selected position.

The whole rear sight assembly can then be removed by sliding rearward.

Next, remove the two screws located on the top of the front sight plate and remove the plate.

This gives access to a third screw… remove it and the front sight assembly can be removed.

Remove the four screws which hold the inner barrel guide plate in place and gently pry the plate free from the rear end. Take care at this stage to not damage the battery wiring located in the notch.

With the inner barrel guide plate removed, the gearbox can be lifted free. Slight outward flexing of the receiver shell is needed, and the box can only be partially removed from the receiver at this point. Take care not to foul or pinch the wiring and two connectors to the trigger assembly while removing the gearbox.

The gearbox is gearbox is now free and clear of the receiver.

The Gearbox

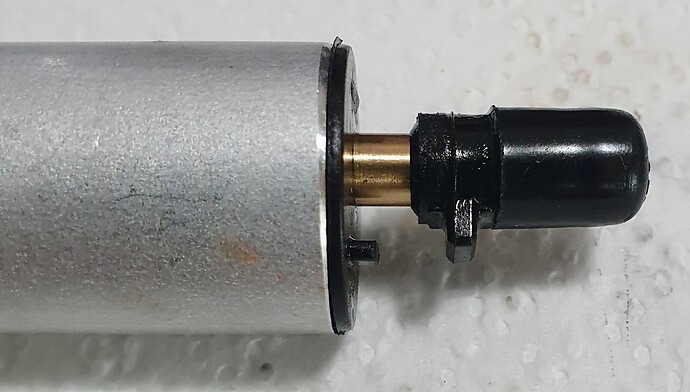

Looks to be 100% proprietry, similar to the Le Hui MP9 gearboxes in size, so basically a pistol gearbox with very little cylinder volume.

What jumps out at you immediately is how incredibly under volumed for the length of the inner barrel this blaster seems to be, which comes in at a surprising length of around 25cm!!

By comparison, an MP9 inner barrel comes in at around 10cms and that’s hitting around 210FPS. Testing different length barrels on the MP9 showed that with the very small cylinder volume, any increase in length dropped FPS markedly, so that long barrel would be giving horrendous VE and probably causing vacuuming and gel drag.

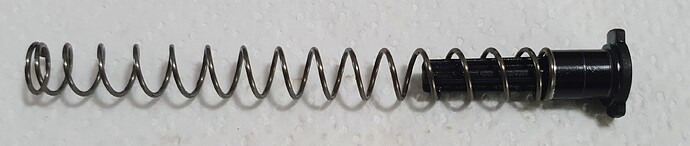

The first modication therefore is to the inner barrel length, i.e. shorten it by 8cms, the inner barrel will finish about a centimetre into the front outer barrel assembly. Should increase the FPS significantly, with a new inner barrel length of around 18cms.

Still not ideal VE but about as short as it can practically be. The inside diameter of the outer barrel is 10mm, which shouldn’t create problems with the 7.5mmID inner.

Shortening the barrel from the front is easiest but does mean losing the rubber hop up. It CAN however be shortened at the t piece end by tapping the plastic collar off.

NOTE : If the barrel’s shortened at the t piece end, it will require modification as does the receiver. The collar has a moulded detent strip which prevents rotarion and a corresponding groove in the inner barrel. To refit the chopped barrel into the collar, a flat is required to be filed on it to clear the strip.

There is also a machined groove in the factory barrel, about 9.0mm in diameter (see photo). The corresponding hole in the receiver is also 9.0mm. With the end cut off and that groove no longer there, the receiver needs to have that hole opened out to 9.5mm for the two shell halves to close up on reassembly.

My plan is to shorten at the hop up end and fit an adjustable 11mm hop up. The outer barrel will need to be bored out to around 12mm to accomodate the hop up.

Shortened inner barrel.

Reassemble everything in the reverse order to the steps above. Simples!![]()

The Result

Putting a few through the chrono to check for any improvement, the shortened barrel showed a gain of about 30FPS. Not stellar but a gain just the same. It’s now sitting on about 170FPS, still slightly lower than X-Force’s review results but closer to their demonstrated 175FPS.

The test gels may have been a little old, so fresh gels brewing as I write to eliminate innacuracies and variables. After that, if it’s still low the gearbox comes apart to see if there’s anything to be improved there, maybe a spring upgrade / modification.

Stay tuned, more to come. ![]()