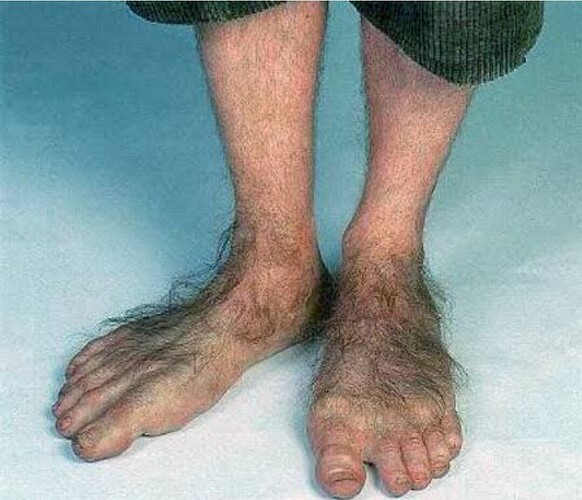

Foot Porn Shot…

Nice…!! ![]()

![]()

hahaha … i think that might shut down any future toe shots for good!

If I get a single pinky in a photo I crop it out…

I know you guys too well… like flies on a t-bone with that shit. ![]()

Took a long overdue look at the double feeding issue on the Gel Fight VZ61 Skorpion.

Pre mod it was hitting around 160FPS on the chrono but of the 40 or so shot capacity one in 5 would double feed and flub out of the barrel. Looking at how gels sit in the very proprietry t piece it was easy to see how they can double up.

Tried the old o ring glued into the t piece trick to reduce the available space but gels were exploding out of the barrel. The molding isn’t clean so I drilled out the seat area to give me a flat surface for the o ring and glued a fresh one in. A little too tight so did a bit of creative sanding of the ID and it now feeds Ultras consistently and is sitting around 200FPS. ![]()

If anyone had one of the early versions of gel sorter that WAT got in that had the funky threads, I made some adaptors if needed.

Been pretty quiet on the build front on here for a while… ![]() so here we go…

so here we go…

Today’s project, trying to turn an incredibly uncomfortable EM Cannon into something useable.

The fixed stock, although cool looking, is horrid to use. The handy but badly positioned housing for the battery indicator makes getting a decent line of sight through the DD iron sights impossible and digs into your cheek. A crane stock provides a much better cheek weld and the sights just fall into line with your right eye. No great loss losing the battery indicator.

Next job is to piff the green idiot lights in the front of the handguard then incorporate a torch and pressure pad, probably shorten the outer barrel so it doesn’t cast a shadow in the field of view.

Something a little different and nothing better to do on a shitty rainy day.

Well… pun intended!

The well g36c I bought not too long ago was a abs body, polycarbonate gearbox version.

It worked, got 200-220fps… a bit lackluster to say the least by today’s standards.

I opened it up, with the intention of improving seals, maybe a 1.18 spring or a JG spring to push it a bit closer to the 300fps mark.

No spring fits on the spring retainer, the throat of it is too wide… I have a v3 steel bearing retainer that could fit, with loads of filing…

Then I stumbled on "I wonder if that v3 JG box from a sig would be similar, and you bet you arse it is!

So similar in fact, the well g36c cylinder head and cylinder fits. The tappet didn’t but the JG tappet fits the well nozzle! The motor cage from the well fits the JG box… even the selector, trigger and associated stuff fits…so I am doing it! The only hurdle left is to get the trigger switch in and wired up… then it’s just grease it up assemble and send it.

So it will have a JG neo motor. 13:1 gears short 4 teeth, probably an m110 spring.

Also has a stainless well cylinder, SHS piston with the JG head, everything so far looks like it won’t just work. It will work well!

Also for fun, check out the nonsense length on the nozzle

Frankenblasters… love 'em! ![]()

Great to see! ![]()

Spent the morning combining parts from the trigger switch and assembly from the JG sig box and the wells g36 box, got everything working on the bench so mild win.

It was basically the electrical parts and trigger from the g36 in the Sig trigger block. Tool a bit of trial and error.

Since I had to file the casing lug off to fit a normal un-notched cylinder I also gave it a nice radius job as I have seen these break, likely as they are so easy to change the spring to a larger one.

Now just have to wire it up, going to replace the wells silver wire with something better and might as well run an easyfet since I have a few, and I don’t want to repair and canabilise two switches again.

Mocked it all up in the receiver with the barrel to test seals which are too good, the nozzle doesn’t travel back far enough to have proper room to feed gels, it had some feed issues before with the stock box but the JG tappet doesn’t draw it back quite as much, exacerbating the problem.

The wells tappet is very weak, flexy, and doesn’t fit the JG box by about 0.6mm width, and thickness is a similar problem.

I’ll take the day off for some Easter family things and come back to it.

But ATM I am thinking I will trim 1-1.5mm from the nozzle and the back of the nozzle rubber. That or I will makeshift lathe the nozzle down though that has the risk of weakening the end of the nozzle as internally the bore gets wider just past the section the nozzle rubber goes over.

I’ve got a bigger than normal piston spring you can have if it helps you out. ![]()

Too big to fit into a standard piston, not even sure what it came out of.

It’s a 1.25mm spring with a bigger ID of around 13.2mm, 180mm long. Let me know if it’s of use to you and we’ll work it out. ![]()

I don’t mind keeping AusPost viable ![]()

Cheers mate but I’ve solidly moved on with the JG gearbox that will happily take normal springs.

Shortened the nozzle, hopefully enough and if not I can always shorten it a little more. Didn’t want to go too much as there is no undo button for it. Trimmed the rubber tip down then files the nozzle down, glued tip on and on the bench it feeds 7.5mm gels easily enough they just pop in through the tip.

Still has a good seal with a couple mm of squish so fingers crossed!

Then spent the morning installing new wiring with an easyfet. Came up nice.

CBF greasing the gears and putting it together today so will finish it during the week.

Still have a few tweaks and touches I want to put on the body of it before I get to assemble it.

Got a bit further this morning, cleaned lubed and assembled the gearbox. Then spent an hour combining it with well g36c safety mechanism. Getting there! ![]()

You can see the wells g36 part as it is clear. Had to trim and modify it slightly to sit flat and use a longer screw at the front but it fits and works at this stage so another win.

Nice, was looking at one of these and tinkering with plans to adapt one altho a bit diffrent cause i have 0 idea how to do threads but youve just saved me the headache, thanks will print them eventualy and let you know how it goes.

Current update is it works! Sorta…

Got it all together, everything fits and works as it’s meant to. But I need to shorten the nozzle a little more as it won’t quite feed normal size gels. Smaller gels are okay but I like full size gels and 7.5mm barrels so back apart it comes.

And this thing is an absolute shit stain to put together. Makes me very grateful we have moved to split receivers and don’t do clamshells anymore.

Anyway when it did feed it got an expected 260-270fps on an m100 with it being short 4 teeth. Currently glad it is going to work out, and at the same time a bit annoyed at myself for not shaving a bit more off the nozzle but hey, bench test vs in practice is all I can say.

Also quite happy it sounds like 11v stock blaster fire rate when run on a 7v! And sounds about 25rps on 11v.

So back in the bench it goes.

Sorry, this message does not exist

I am working on a stock M4A1 cyma CQB, a v2 gearbox, and plenty of modding potential

Overall, even as a stock blaster currently, it performs well, and will upgrade it soon

If i where you i would bite my tounge and refrain from being crude to other members if you want them to help you, remeber we are a isolated community in qld but the network of bad people flows fast, dont become our kicking muskwang because your young (kicking mustang on youtube but i call him mustwang because he just gover over the top with shooting people in the head or the nether region)

Whoah…… where’s this all about @Jakedestr0yer ! ![]()

I can’t see where anyone has insulted each other in the comments here?

Gotta play nice and pay respect towards each other, otherwise I’m going to have to bring down the hammer on anyone not playing nice.

Shoot me a PM @saph if there’s something else going on in the background that we aren’t aware of.

Sorry, didn’t actually take insult, just am sometimes called a kid and made it to a joke. Really sorry