Crazy enough, it might just work ![]()

Waddaya mean you might have problems?

You’ve always been a nutcase from the very start! ![]()

![]()

In my defence, I never said ‘might’![]()

I like! I have a similar, though not as nice supressor going on mine whenever new gears arrive.

Hows the stock attach?

Screw and nut with shake proof washer through the rear plate.

There is a 3d file out there for buffer tube rear plate👍

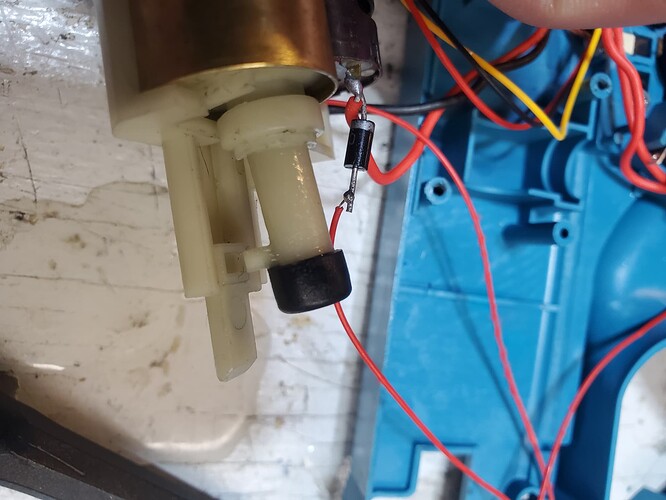

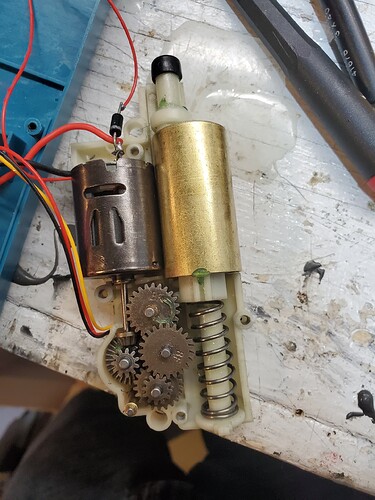

FINALLY got yhe new metal gears into the blaster. The pitch is different on the pinion/primary spur from stock and these need to be shimmed.

Iv gotten pretty good at assembly for this gearbox. Theres a few tricks that are key. Use the tappet plate to push the return spring in. The cylinder head has a specific orientation, with the nozzel on the bottom. And most importantly, the nozzle slots into the tappet plate. The nozzel needs to be fully extended during assembly. This is what caused my plastic gears to origionally strip, and untold rebuilds of this gearbox.

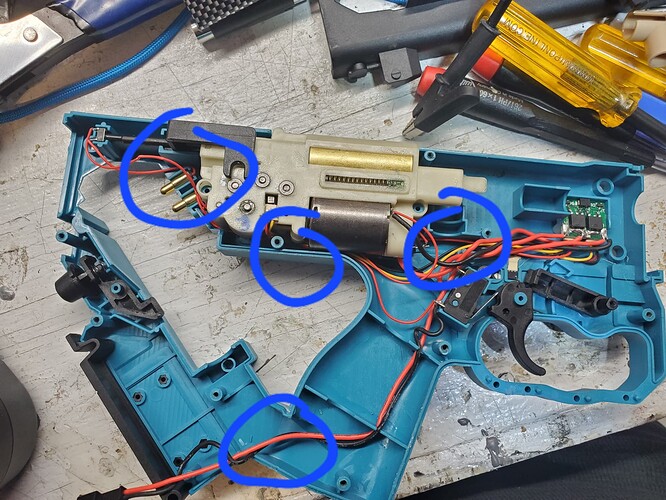

Theres a few places where the wires are easily smashed inside the clamshell, circled in blue.

Finally assembled, results were lackluster. ~150 fps. I cut down the barrel, ended up at 100mm. Got better, but still poor 150-175fps. So all this work, no gain. Ill tear it down again, play with the piston seal and maybe stretch the spring some more - it dosent sound like it being punished too bad.

Nice work and great details/information, thanks for sharing ![]()

Surely it has to be seals🤔

Been looking for an o’ring nozzle for these but no luck so far😔

Let me know if you find anything. The piston seal and the cyclinder seal leave some to be desired.

Evidently my home made green oring isnt cutting it

Just wrapping the cyl head oring area with plumbers tape till it’s a real tight fit usually works🤔

Nozzle is another thing altogether ![]()

Good day to all.

I just received my Quasar via B709 permit.

Can I ask if any is experiencing gels dribbling out on single fire at 7.4v. Two batteries that came with it have been tested.

At 11.1v I have no issue on single or full auto.

-z

The stock barrel is oversized causing it to not hold the ball in place. Pretty sure thats what caused my double feeds and dribble. Change the barrel to a 7.5mm alloy. Hopfully youll get lucky and it wont be glued in.

Metal gears arrived last week, not sure when I’ll get around to actually putting them in as still too shaky at the moment🤔

Would be nice if we could get a metal ladder piston as well, I see this as the next failure point with any spring upgrade🙄

I believe X-Force were getting in the gearboxes with metal internals, whether they have metal ladders of course is another thing. I think they were waiting on China clearance ![]()

Gonna keep searching down the Well airsoft mp7 route for now.

Please post if you find anything. I cannot locate a better piston/ladder.

The lehui mp9 cylinder set up looks very similar. Ordered this to see. Its too funky a design to not be the same.

Metal gears doing fine so far. Had maybe 1000 balls through it, so not much. But still ticking over without any new noises.

Watch the pinion/spur mesh. There isnt much wiggle room between slipping and grinding.

Thank you Chapinb. In reading your earlier posts, I can now see the connection you made to the barrel ID.

I intend to do a barrel swap over the weekend with an offcut of 7.5mm alloy that I have from a prior mod.

I also read about your barrel being super glued into the T piece and how much of pain it was to remove. Can I ask what the best trick you found in the end to remove it?

Heat didnt help, at least not without melting the t. I put some acetone (nail polish remover) on it then slowly wedged a small flat head screwdriver between the barrel and t, giving it a twist with plyers every now and again. Go slow, dont want to break the t. It wasnt pretty. But worked.

Thank you Chapinb.

I opened it up and low and behold the barrel was super glued.

Given your difficulty, my first reaction was that I was going to ask a 3D printing company that I have had good experiences with in Brisbane to print a T-Piece in nylon.

In the end I was able to dislodge the barrel from the t-piece by heating the barrel directly with a soldering iron. It seemed to break down the bond of the superglue and came out with a little effort.

So no need for the 3D printers to work out the geometry and print, but I did see that they are doing parts in carbon fibre. I imagine nylon would still be best for a t-piece, but some carbon fibre would be good for other parts.

-Z

Never thought about heating with a soldering iron. I like that idea.

I printed a nylon hopup recently thats untested, but hopful it works well.