Next part… the mag spring (FIX) (Sort of)

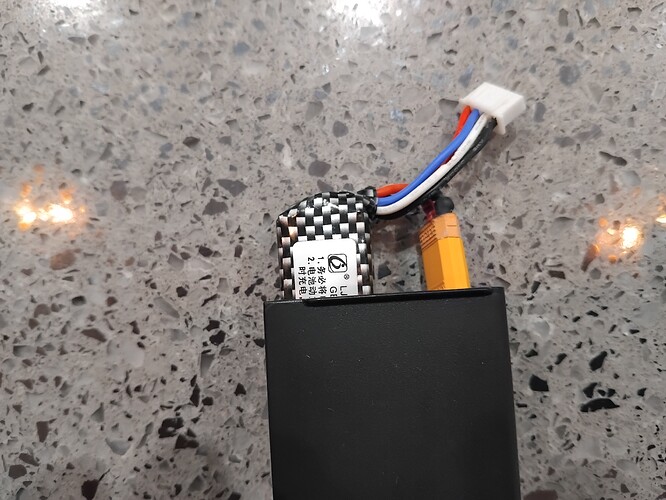

Here is a comparo of LDT MP-5 spring mag , vs the Sten…

LDT on the left.

Just as i thought, the LDT has a stiffer, thicker, firmer spring.

@Maiphut , mind out of the gutter…!!

Also, the LDT spring is not free floating, each free end is firmly attached into the top and bottom of its mag components.

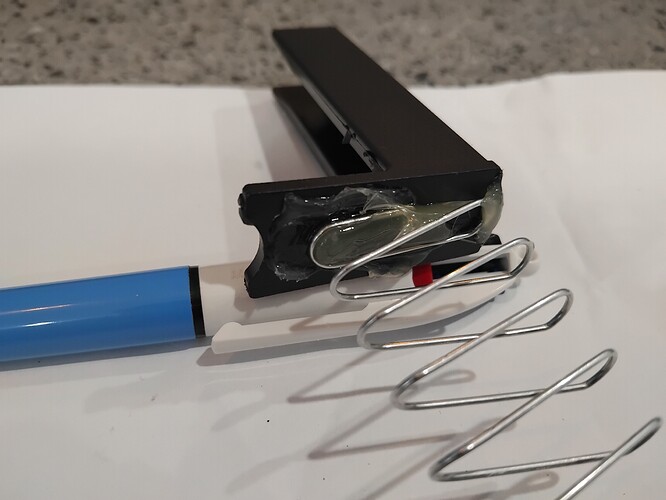

This is the offending free end, of the Sten…

Same free end, at the top and bottom…

It cant wait, to jam into something…

Like a pollie at election time, it buckles under pressure, and jams the whole spring up…

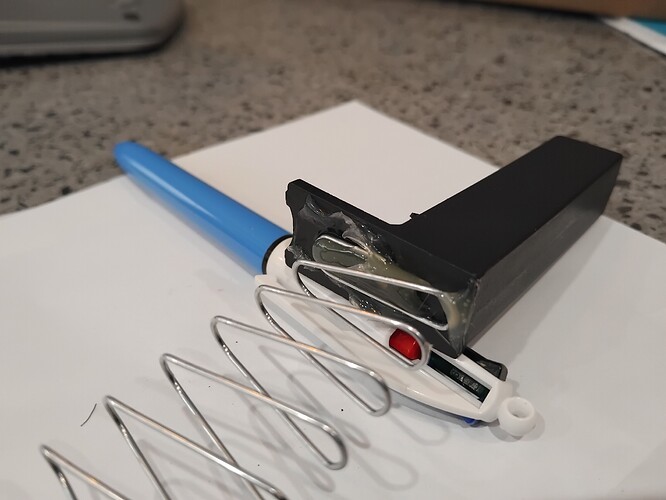

My trial solution, was to embed the top end of the spring, into hot glue gun glue…

This embeds the pointy free end, and contains it.

I only did it on the top end, the bottom end will be under compression via the spring.

Also, on spring withdrawl, you are pulling the top end out via the plastic component, with no real force on the spring/glue interface.

If the very bottom one was glued in, it would be dragged up by the glue, and hot glue isn’t all that strong. Being unbound at the bottom, allows the spring to rotate a bit too…

I was going to do some more firing / testing tonight, but i have buggered the battery, and should do the thommy review as well…

@AKgelblaster , attaching the spring to the mag top with stronger glue, should solve the mag problem somewhat… it was always the top part of the spring that buckled and folded…if its glued on, it cant…

Tell that to the factory…

And, also tell Jing Ming to make some Nice Uzi’s…!!

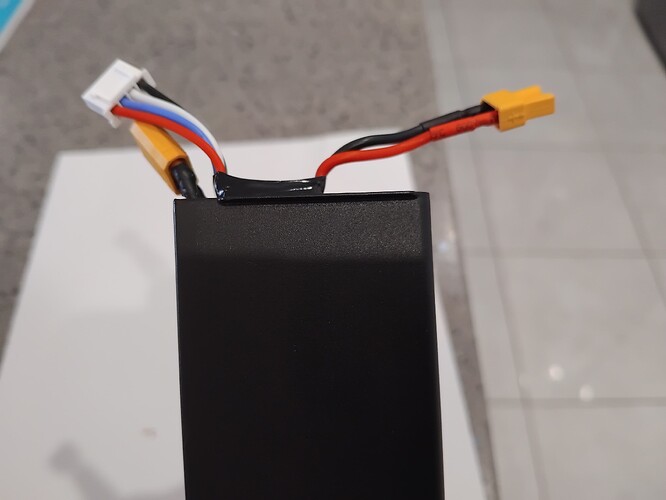

ALSO: for those interested, NO, the LDT MP5 mags DONT work with the new JM MP5-k…

it doesn’t have the protruding terminals ( but you could potentially add them on)

![]() The crude sights let you down. Much better with a red dot on top.

The crude sights let you down. Much better with a red dot on top.