As I checked, the top has a part rotate and push a gel out from each bolt action.

I just poured a lot of silicone lube, into the push mechanism.

It seems to be turning, ( and clicking) better than before.

We’ll see how it goes 2morrow…

Ok…Mag update…

I have figured out the problem with the sten mag.

It has no electric motor, just a manually actuated wheel, which spins and pushes gels forward.

Its 3d printed.

The mag is currently out.

As it sits in the blaster, the gel hole is forward, toward the barrel, and the white protruding bar is rearwards…

This is what happens.

When the trigger is pulled, the firing mechanism moves forwards.

As it travels forwards, it catches on the white protruding block.

The angle on the block, causes it to move forwards, and downwards.

It is mainly the downward pressure, the engages the gel spinning wheel ( with a click), rotates the wheel, and feeds the gels.

The problem is this.

The block can move forwards, but NOT DOWNWARDS ENOUGH.

No Click, No wheel spin.

With the mag out, you can push Downwards on the block, it moves forwards, and clicks every time.

With the mag in, it moves more forwards, and not always downwards enough. Some position on the wheel requires more downwards force, or it gets stuck…this is why it can feed 2 or 3 gels, then the wheel jams…

I have tried filing a bit of the block off…a bit off the front, so it can move forward a bit more…and underneath the block, so it can travel downwards more easily…

No Joy…

All of which is incredibly frustrating, as it leaves you with a blaster that doesn’t feed. I’m quite pissed off.

Whats the answer.?

Have the angled part of the block thicker, and protruding more, so it gets pushed further down.

Good luck glueing anything on that will stick, when it gets smacked by that big cylinder coming forward every time.

It probably needs a 3d reprint, with a taller block, and wider so there is less lateral slop.

My 2nd parcel should arrive soon, with a 2nd gel mag, i’ll see how i go with that.

I am dissapointed that they would release this from the factory like this, i suspect every 3D printed mag will be a little different, lets see what the new parcel brings.

@AKgelblaster , please pass this info onto the factory, and see if they can produce better, working parts.

Thanks.

Yup, I noted that part is probably causing the feeding issue. It happens to me before, spare parts are already in the second parcel, and 3d printing file is available. I would pass the photos and the observation to the designer.

I think the part needs to be redesigned to be taller, so it gets pushed down further.

Pls tell the factory that.

Hey @BME I am passing the issue to the designer.

The designer took a video as follow, he hopes you can show the mag in the same angle as he did, so that he can work out the root cause and troubleshoot it:

Link: https://youtube.com/shorts/bE6Q5gsCEe8?si=Y-bulO3lUFdc-Ap4

Their team is very easy to work with. Let them takes the headache / challenge instead.

Nice bit of diagnosis, BME. ![]()

You could try superglueing a piece of plastic on top of that ramp so that when everything moves forward it pushes the actuator down further. ![]() in other words, building it up higher. I used to do that with the old manual pistol mags to make them more positive.

in other words, building it up higher. I used to do that with the old manual pistol mags to make them more positive.

I thought that 3D printed feed mechanism looked pretty janky… ![]()

I will give it a go, but I have doubts about its longevity.

The big cylinder moving forward , is a lot bigger, and would hit with more oomph, than a pistol…

I will have to look around, and see what plastic is appropriate sized….

Maybe try Gorilla Glue would be stronger than super glue, longer set time though.

Hi @BME While waiting for your video, I checked the mag and the replacement part in the other parcel, the replacement part is a bit thicker, which align with your idea.

You can try anytime to see if it works better. The replacement parts are already in the first parcel:

Here is the video showing how to replace that part:

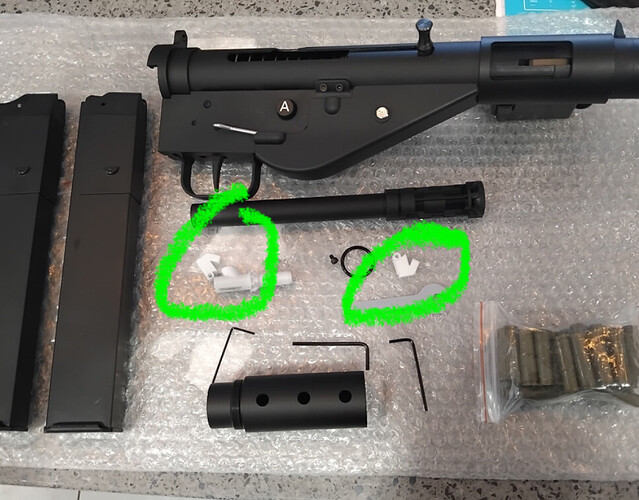

Ok…2nd package arrived.

It has, the rear stock, 2nd gel mag, 2x mag springs, and 2 more lip feed mechanisms, and a spare cocking handle…

I fitted the stock, looks good…

My attention turned to the mag lip parts.

The newer ones, are taller and wider (good).

Comparo…one laying on top of the other…

I pulled the apart, swapped it over, and greased it up…

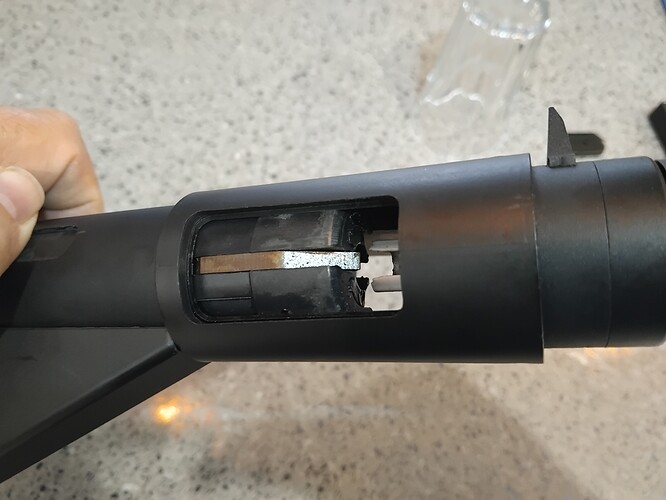

Mag feed mechanism, pulled apart…

The replaced component, is top right…

Put it all back together, and gave it a go…

Good news…it solved the feed problem…!!

Bad news (x2)…

A) its taller, and wants to push the mag back out

B) It broke, after a mag and a half…!! ![]()

![]()

The new mag lip, sits taller than the older one, as it needs to, to have it forced to be pushed down further.

The problem is, there is limited room inside, and it impinges on, and gets hit by, the spring loaded firing cylinder.

In order to engage the mag catch, you need to push the mag in. It now DOESN’T go all the way in ( it used to, with the old one). You need to slightly open the bolt, it clicks and engages, then you can fire. The problem is, the lip fully extends on each cycle to get hit by the cylinder, and this puts backward pressure on the mag.

Enough to force it out of the mag catch.

This disconnects the battery terminals, and stops firing.

I was happy the mag was at least feeding, and emptied the rest of the mag last night. This morning, i refilled the mag, and tried holding the mag in place while firing.

This worked for a while, then it stopped feeding again.

I investigated the mag, the feeding wheel wasn’t turning at all… the new part has broken already…

Comparing it to the other new one…

The mag design on this is faulty.

At the Very VERY least, this component should be cast from metal, to withstand the stress of being struck often, repeatedly, by a big heavy metal block…

This cycling block is what strikes the mag lip…

That big block, is what hits, and cycles the plastic mag lip.

Its like putting plastic brakes, on a freight train, and expecting them to work…

The fix…?

Ideally, you would have a electric motor, feeding gels into the t-piece, and having no contact with the cylinder.

I get that would be difficult to design, and fit.

Should they stick with the current design, then making the mag lip component out of metal would be essential. And the other moving part, it comes into contact with, as well.

That way, you have metal striking metal, the lip can withstand the impact forces, and the rest of the components, not being subject to force of impact, could probably remain 3d printed.

It all comes down , to that one piece, being durable.

It was showing signs of wear and impact on the lip, after 1.5 mags…

Low fps, i can live with.

Non feeding, i cant…

I can work towards a proper solution, but i really think metal parts will be a necessisty for these to work, and last longterm…

Hey @BME Thanks a lot for trying out. I will continue to catch up with the factory on the result of the replacement parts. And if they have new material or shape for it, I will ship you those.

Thanks.

Its extremely frustrating…

I will try the other “newer” mag lip, but i expect it to last about as long as the one that just broke.

It really is a flawed design.

Having that big metal block , hitting hard, on a small plastic tab, was never going to last.

If it doesn’t feed, its unusable.

I have not asked for a refund on any blaster yet, but , if it cant be properly fixed, i would consider doing so…

It seems like they used a printer to prototype the parts, but then just stuck with it for manufacturing.

No printable material would be suitable for a part that small doing what it does. They definitely should be casting that part from metal.

It’s like if you were running metal gears with a nylon piston, the piston will eventually break being the weaker material under such impact forces.

Clearly a cost cutting method but on something that expensive you can’t be cutting corners like that.

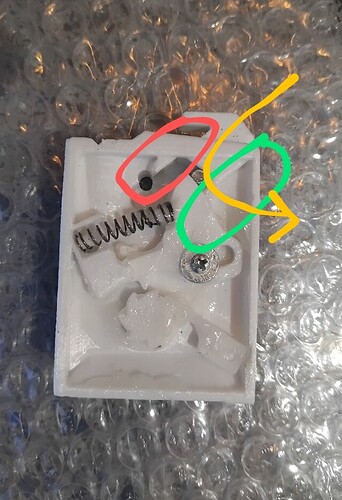

It would appear that there’s a block moulded in front of the push block for support (red), but has nothing to stop the force of the block from tilting backwards when struck (yellow) causing that tiny little pin bracket to snap off ![]()

Adding some material to the moulding behind the block(green) would support it much better and prevent this from breaking.

Maybe form some metal mend into this area for shits and giggles and see how it performs… which it should still work even with the broken section.

Magazine being forced out is also obviously just a design issue created by fitting the revised feed mechanism that wasn’t part of the original specifications… so might be overcome by a little fiddling and filing to get the right tolerances required ![]()

Just like the good old days of modding different brand mags to fit my Gen8’s and SKD blasters ![]()

I agree. Before another material is made for that part, pulling some silicon oil on it will help. It won’t break that easy, still there is a chance that it break.

I will send you new parts once ready.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() 100% BME…

100% BME…

The savage action on that thing is going to either break or wear out a plastic part in fairly short order… even if the designers get it right. I’d even have my doubts about a metal part lasting, unless it’s made out of quality steel and not pot metal. ![]()

I’d be mighty pissed with this if I bought one of these.

The second release 3D feed actuator looks like an attempt to fix it, but maybe a little over zealous about the height of that block. Looks way too high and no doubt the reason why it broke. Too much pressure on it.

I’m gonna start calling you lab rat… I think you’re the subject of an evil experiment. ![]()

And for the record, the manufacturer needs to google the meaning of “R&D” and successful product testing… before selling it.