@BME get back a response, As a temporary workaround, they will reproduce the part in nylon strengthened with fibre next week. I will post to you right after.

Thanks…

But please tell them, metal is the solution…

Hi @BME Yes that’s suggested, the designer replied they tried before but the possibility of breaking the gels in the mag is high the full part is changed to metal.

Translated using Google:

“ the cannot be changed to metal for the time being, use a material made of nylon and fiberglass this time, the strength and other adjustments will be better. Just now I took a look at the picture we mentioned(from @DocBob ) , and I took a look. Well, we will follow some of the suggestions in this picture, and then change its overall design. We will make a little effort on the stress-bearing structure. After making this structure, it will not have this kind of forward leaning. kind of phenomenon.“

Great communication, I’m really impressed. Let’s look forward to a product improvement. ![]()

Not that I’ve seen the replica blaster but I didn’t realize the bolt was made of metal, if anything like the real one in weight and some of BME’s pics it looks similar would be harsh on plastics of all sorts.

Why the metal bolt, just thinking. For the shell extraction, I can see they’ve replicated the og Sten extraction. If the bolt was remade in nylon. Forget about the shell extractor unless that is a big market somewhere ![]()

what about two separate versions if there’s a strong market for both gel and shell ejecting?

stands to reason that separating variants, metal bolt for shell ejecting if it’s currently working better setup for shell ejection,

and nylon bolt for gels, if that’s the issue

what’s the feedback from people using it setup for shell ejection only? (if any)

are they having issues as well or is it only people using it for gels only that are having issues?

one version for shells, a different version for gels.

each version made specific to cater for each shell ejection and gel may be the solution

for shell ejection, the whole white, 3d printed motor is removed.

Purely the spring , pushing the shells forward, into the chamber.

Nothing gets “chambered”, the spring pressure just pushes them all the way through, and out.

So, no part of the feeding mechanism is in direct contact with the big, bad, bruising, busting bolt…

just a thought, my misunderSTENding

I’ll sit down now ![]()

![]()

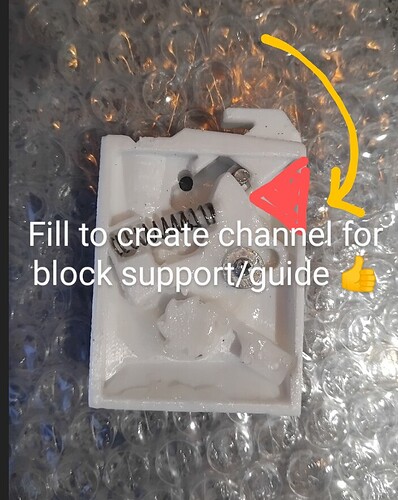

Maybe the manufacturer’s looking at this from the wrong angle.

Instead of making the feed wheel mechanism stronger, which I believe is a futile exercise, maybe they should do as Maiphut suggests and change that sledgehammer of a pushrod over to nylon.

It only has to push down that block to get the wheel spinning, it doesn’t work hard. And I still thing downgrading the bolt springs to take some of the savagery out of it wouldn’t be a bad idea. I get that the shake rattle and roll adds to the realism but you have to wonder how long it’ll survive intact slapping as hard as it does. Remember most of us disable violent blowback mechs on blasters that have them to try to increase the lifespan of them… this one’s got it in spades by design.

Seems like a case of the designers doing something they could without really considering if they should.

All I was thinking was metal even if it is pot metal, and I know how heavy a Sten bolt is a monster lump by design to get the thing to run. In all metal form that can absorb impact and abrasion way more than common plastics. Metal on plastic does not usually work well.

Seeing as the tube is plastic (unless I’m mistaken) why not try a Nylon or whatever printed plastic bolt that could be swapped out with a lighter spring set to go from shell ejection to straight up gel ball. If close to original Sten in design this would be a very easy swap.

Most of the Australian market I would say are not very interested in shell ejection.

If all those mag pieces were made from metal…it would work flawlessly…

If you want a plastic piston, m416gelblaster sell a 3d printed shell ejector…

I have my doubts, about it though…

weird tho,

their listing shows it as black but the video orange and blue

definitely wouldn’t want an orange n black one, altho could always paint it

Could of just been a prototype made with whatever colour they had on hand, not uncommon to do something like that then use a specific colour for production units.

One way to get a t-rod stock….

But, it would probably melt on the way over…

have you seen this one?

says it’s only shell ejection as far as I can tell

but the listing has it under Airsoft

being that it doesn’t fire gels or bb’s, would that still be able to be imported?

AU$91

realised it’s only 1/3 size, but still looks cool

I’ve bought plenty of stuff from SIXmm with no problems. Good company to deal with for accessories and attachments. ![]()

BME would be the one to give you a better idea about maybe bringing in that 1/3 scale replica. BorderForce and Customs can be funny buggers. ![]()

I’m pretty sure he said that shell ejecting blasters require the b709a, doesn’t shoot projectiles so theoretically you’d think should be able to

Still a replica, which in Queensland falls in the restricted item category. B709a required would be my guess.

Just tell BF you’re arming a group of Oompaloompa resistance fighters.