Okay, Jin Ming MP5k is done to my satisfaction… lots to read here but may help others, particularly newbies thinking of getting one of these. They’re cheap, externally quite good and would be quite a popular choice for a first blaster… buckle up, this is a mofo big post.

Started out this morning with a complete tear down as follows :

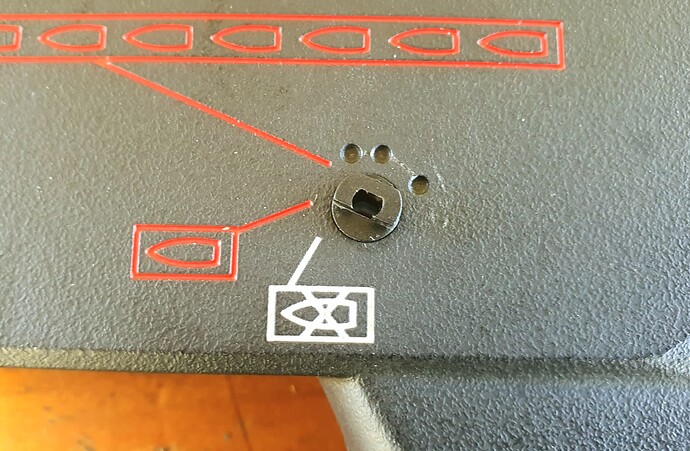

With mag out, and foregrip off, remove the four Phillips countersunk screws pictured to remove the front assembly.

Then throw them away and replace them with roundhead screws… the countersunk heads bury themselves into the nylon and once below the front assembly are arseholes to get out again. With the screws out remove the front barrel / charging assembly.

I found with this one the charging handle wasn’t rotating enough to lock into the detent securely, so I removed about 1mm of material from this side of the tube to allow more rotation and better lock.

Remove the buttcap from the back and undo the large screw on the bottom.

If like this one the blowback has been disabled, the rear plate, recoil rod and dust cover assembly will slide out rearward.

If the blowback hasn’t been disabled the assembly has to stay located on top of the gearbox until the upper receiver has been removed.

Slide the upper receiver forward keeping tabs on the battery wires and inner barrel / t piece so they don’t snag or foul.

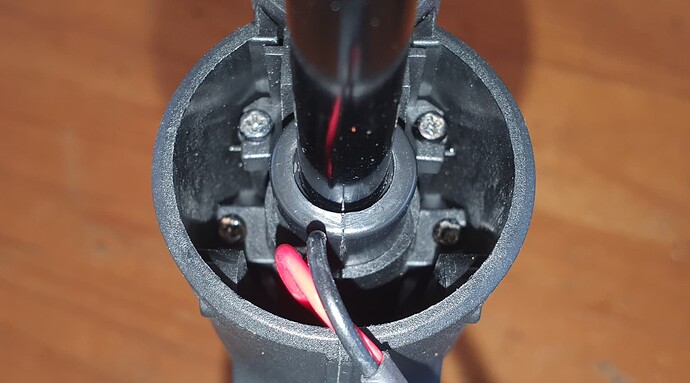

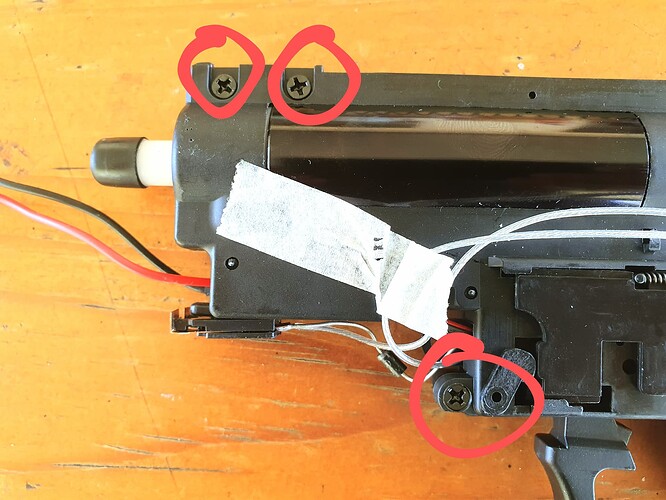

Remove the two screws on the motor base, unclip the motor wires and carefully remove the motor.

With the ambi fire select lever in semi auto, loosen / remove the small screw securing the left side lever and remove the lever.

Remove the right side lever and connecting rod.

With the motor out, remove the two screws in the grip which secure the gearbox to the lower receiver.

Carefully feed the motor wires through the holes in the lower receiver, pull the gearbox upwards to release it.

Take care not to lose the fire select plate on the left side of the lower receiver.

Remove the piston spring retainer and the piston spring before taking any screws out of the gearbox. There are three screws on the left side of the box, and seven on the right, six large one small.

There’s no need to remove anything from the mag terminal assembly, Jin Ming made that well, even if they did pinch it from Golden Eagle MP5s.

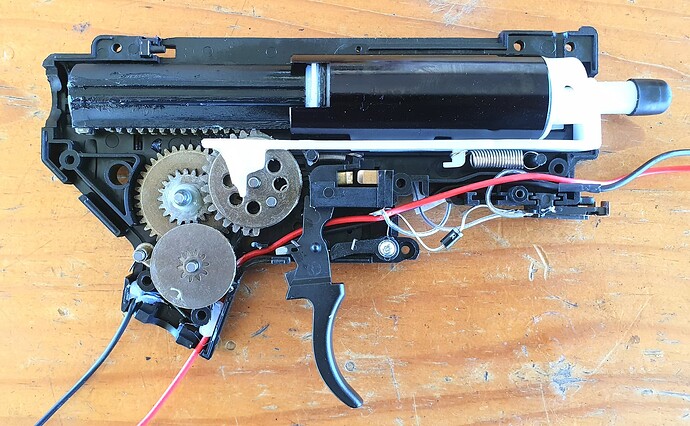

Remove the right side of the gearbox shell to access the gearbox internals.

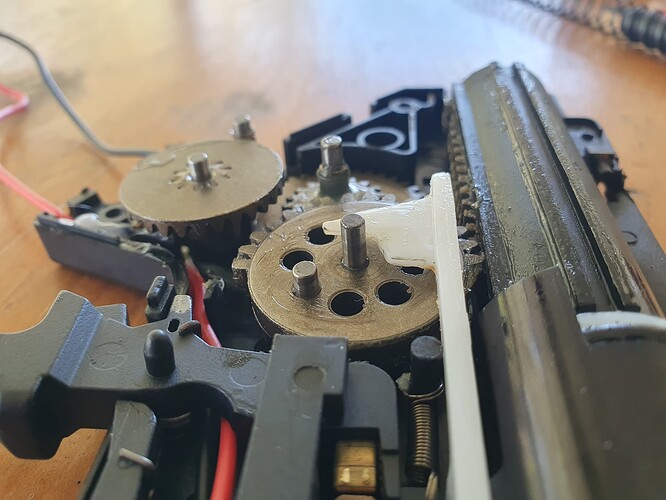

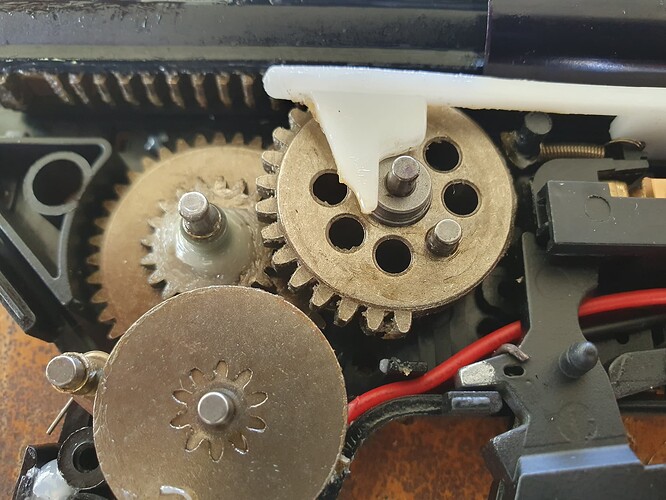

Here’s where mine gets interesting. The right side sector gear bush had fallen back into the gearbox and onto the sector gear.

Jin Ming neglected to fit the little bronze spacer onto the right side of the sector gear, so in effect that gear had upwards of 5-6mm of endplay. It allowed the gear tons of movement, dropped the bush out of the shell and left the gear unsupported, which could have damaged the gearbox shell, damaged the piston rack, seized the gearing, caused a lipo fire… I can go on.

No shims to see anywhere so clearly the factory literally threw everything in and closed it up.

Airseal was pathetic with the factory components, which are all Gen 8, by the way. The OEM cylinder appear to be about a 90% unit, way too much for the 11cm inner barrel.

All new upgrade airseal parts installed. 60-70% ported cylinder, double o ring alloy nozzle, upgrade piston head and o ring. The alloy cylinder head couldn’t be used as the holes were mislocated so I ran with the nylon JM head, compression is stellar.

Sector gear replaced, all gears shimmed correctly and lubed, the box reassembled with an M90 piston spring. The blaster reassembly is as above in reverse order taking care to have the left side fire select plate in semi auto and in position.

Some of the other issues fixed on reassembly:

The t piece is a split unit, the inner barrel is located and sealed with a plastic adaptor fitted to it.

Except this was neither sealed nor located.

I used a wrap of electrical tape to build up the diameter of the adaptor and secure it tightly in the t piece, which was glued securely.

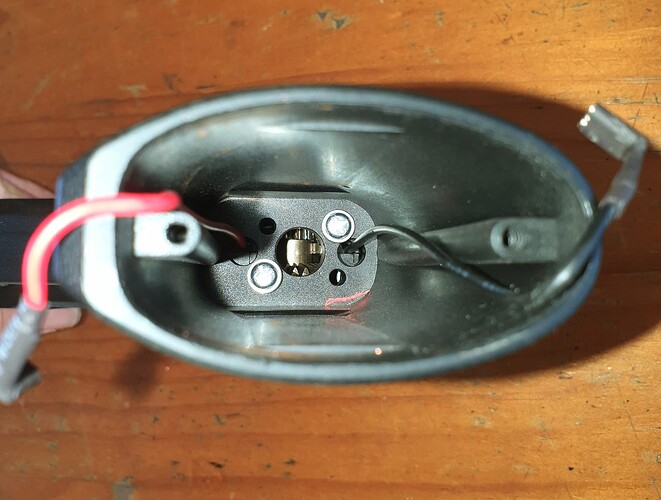

The rear alloy plate that secures the blowback unit’s screwed to the piston spring retainer. Jin Ming uses a dirty great self tapping screw for that, always works loose.

Easy to replace with a metal spring retainer and a 6mm screw held with a little Loctite, but I didn’t have a metal retainer that fit… so I tapped out the plastic retainer and installed 6mm threaded insert.

Everything’s held in place with a 6mm hex button head stainless screw now.

Motor pinion gear was missing a grub screw and had a little movement as a result.

It’s got one now. Also added a small o ring behind the wear plate to stop rattle.

All back together and reading about 190-200FPS on my chrono with WI reds which are usually a little small. I’m keen to test it with larger pinks, it doesn’t like Ultras with that low power. I reckon it’s about as good as I’m going to get out of an 11cm barrel. Noticeably quieter and much more accurate now with the ported cylinder correcting the appalling VE it had. Almost sounds suppressed and the box feels far less stressed under use now.

Hope this helps out any newbies who buy one of these. I’d definitely recommend checking everything out with the gearbox before hammering it at gameplay.

And I wouldn’t recommend asking a shop tech to do all this… it’d cost more than you paid for the blaster and they’re not as OCD as I am.

![]() ).

).![]()