that definitely looks a bit out of place lol

What’s that stock from? Thompson or something?

yeah…from a 2nd hand thompson i got, so i could have a spare gearbox, for the P.R…

Its not attached, just a joke /mock up.

Obviously sitting Waaayyyy to low…

With the stock shouldered, the blaster would be above eye height…!

You know those jobs that are so worthwhile but you have to go through a bit of pain to get to the end result? ![]()

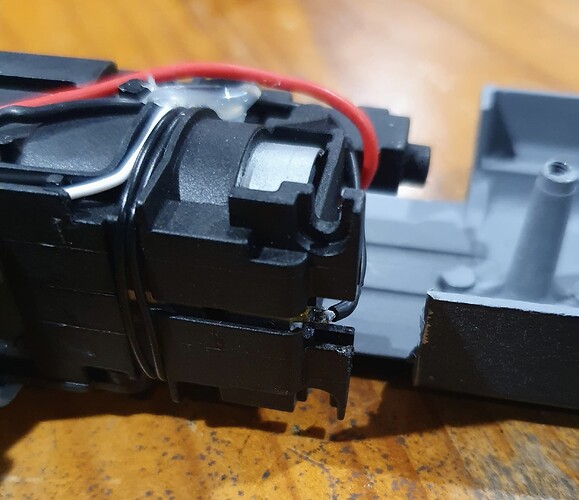

After a layoff and a mustering of motivation, work’s back on with BME’s UZI cap gun conversion. ![]() :

:

I had a feeling it was going to be a tough job, the Spanish UZI cap gun is made of some solid cast metal, maybe steel. Five hours in the shed with a Dremel and a stack of cutoff wheels has it by the balls, however.

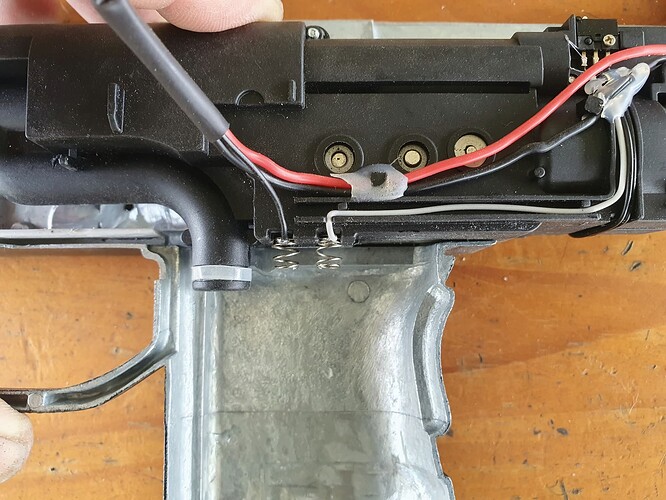

The MP9 gearbox’s snugged down as low as it can practically go in the shell, any lower and the integrity of the grip’s compromised

Even at that low height there’s still a little misalignment with the shell barrel, but with the barrel trimmed to length it definitely won’t be noticeable and any tendancy to shoot at downward angle can be corrected by holding it on it’s side like an L.A. gangbanger. ![]()

The bottom of the grip’s been cleared away to take the MP9 mag, which will be guided by inserts and retained by voodoo yet to be determined. The mag terminal springs and feed tube fall short by a couple of millimetres but they’ll be easily extended. ![]()

All gutted, primed and ready for phase II… good times! ![]()

Looks awesome…!!

Nice long barrel, too…

Should be able to get its 200 fps out of it…

Will a gen 8 fit?? ![]()

![]()

![]()

I’d happily put a Gen 8 in a UMP for you… ![]()

Funny you mention that, …

I bought my UMP for $135, BME… with a Gen 8 in it. ![]()

I have an old rattler UMP…with an upgraded gen8…!

Nice work mate, looking awesome ![]()

I have a very high opinion of these UMPs… they were ahead of the game in their day… and soooo light. I love a light SMG, I compared this to the Gen 8 EVO 3 I have, similar size and config but that’s a brick compared to the UMP.

Wouldn’t mind one of the LDT variants… one day. ![]()

@DocBob thankee kindly, Doc. It’s certainly a challenge. ![]()

Long arse reply @Friendly_Fire ![]()

Just finished the last of one pint and 1/4 way through my second and still waiting ![]()

The UMP’s were definitely a favourite of mine for their solid build, Gen8 powered and still highly customisable despite their simplicity ![]()

I still have quite a few of them packed away somewhere brand new, never assembled, along with the same amount of Singularity Gearboxes still in their original packaging…as well as probably about a dozen spare magazines and different aftermarket handguards, buttstocks, metal rail kits etc ![]()

Big day on BME’s UZI… ![]()

Gearbox is in, still to be locked down but I’ve got some ideas for that.

Magwell has been boxed in for the MP9 magazine, and while not sorted with mag retention yet, it’s together enough to hold the shell together with tape and test fire as proof of concept. ![]()

Short video of first firing

With the temprary extended barrel it’s only showing about 150FPS on the chrono running a 7.4v lipo. But it is the only functional standard UZI gel blaster around… that I’m aware of at any rate. ![]()

Still have to fabricate a cover for the rear end of the gearbox where the UZI shell’s been cut away, build a battery box under the top cover, fit a trigger return spring and get my head around retaining that mag.

Neodymium magnets spring to mind. ![]()

So the gameplan moving forward is : ![]()

Make up a plate that top screws into this two piece screw mount, either side of the existing 3mm thread to keep the two shell halves together in the absence of the original screw.

Drill out the 3mm thread to 4mm tapping drill size and tap the connector plate M4, then drill the old 3mm threaded hole out to 4.5mm.

Use a fake charging handle with M4 thread to hold the top cover on. The back end of the top cover slots into a detent under the top of the shell and is held secure.

Attach a rubber block to the underside of the top cover to hold the t piece end of the gearbox down against the shell vertically.

Bend up a box section cover to hide the bottom back end of the gearbox which sits out of this cutout in the shell.

Top screw M3 into the box cover at these two original screw mounts to secure the back end of the gearbox and prevent it moving forward or backwards.

Fabricate a battery compartment above the inner barrel. Access is by unscrewing the fake charging handle and removing the top cover, so very easy access for battery swaps.

Install two high density foam rubber blocks above the mag pads on the sides of the magwell to grip the top of the magazine tightly and hopefully hold the mag securely during cycling. If not, plan B. ![]()

The shell will hold together by one screw at the rear, the top cover which folds over from the top, the connector plate at the charging handle, the box cover at the rear and a friction fit ring over the outer barrel on the front. The only tricky bit will be the grip, I suspect a wrap or two of tape is about all we can do there due to the mag access.

So still a fair bit to sort out, but we’ve broken the back of the majority of the tricky stuff. ![]()

You okay with all that, @BME ? ![]()

Suggestions? Changes?

Because… you know… the customer’s always right! ![]()

Think he’s still scraping himself up off the floor ![]()

![]()

Top job man, really impressive. ![]()

Let’s see…

Cycling bolt with blowback action,

Shell ejecting, at the same time as firing gels,

Removable, and extendable stock,

Strobing smoke and laser light,

“ Da Ooozi nine millimeeda “ Arnold voice on hidden speaker and,

Capability to swap barrel and mag, to chamber the real thing…

Sound reasonable…??

In all seriousness, looks awesome.

Can’t wait to get it…!

I. Happy to try the friction fit mag, if need be, can supplement with a wedge at the bottom.

That would avoid drilling through, for a pin retention…