V2 compared to V3

Damn, that takes me back. I miss ol’ Novice Driver Productions ![]()

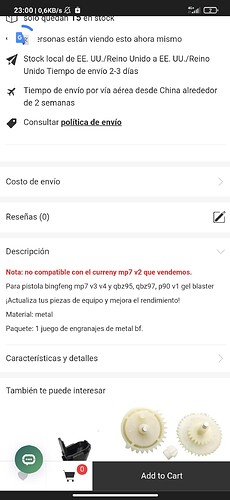

so is it compatible with v2 and v3? more than anything it’s because of the gears

sorry… i uploaded it translated… basically what it says in the product is that it is not compatible with v2

I am interested in the SIG 552 and am curious to know what mods or accessories you may have added. Cheers.

Hey @DocBob I got a question for you, figure you might know having worked cars for so long. Not specifically an AEG question, but it may help people later.

I’m trying to put a table together at the moment, and I’m having a problem with one of my bolts/nuts. I only have one of each, so I can’t just swap them out on a whim.

I’m trying to tighten the nut down on it, so that it’s tight enough that the leg doesn’t wobble, and I can get it fairly tight, but when I make that final little turn, it’s like the thread suddenly slips back a few slots?

It’s not stripping the thread, I can tighten it back down to that nearly-perfect spot again, but then it inevitably slips again. The table’s going to be taking a few heavy thumps on it (it’s my workbench, so tools being dropped on it etc), so I want the nut/bolt to be sturdy.

I’ve tried wrapping it in electrical tape, but 1 layer still causes it to slip, and 2 layers is too thick and gets cut up by the nut’s thread. What should I do? My current ideas are plumbing tape, or loctite. Is there any better solution?

Washers.

20 characters

It must be stripped either the nut or bolt, I’d be going for a new one.

I agree with @Maiphut

Probably the actual thread on the bolt where it leads into the shank.

Try packing a washer or two under the nut and see if it makes a difference, as this will step the nut back away from the problem area on the threads.

China bolts aren’t quite renowned for proper sizing/thread engagement…… so could be the nut and bolt are both incorrectly threaded ![]()

Anything for that matter, even my “Aussie built” 20Mx10Mx5.5M shed kit came with jacked up bolts for the tension straps. All metric until I hit that one they started out metric and half way through was wtf cross threading and stuff, paused checked it out yep they mixed in some imperial nuts ![]()

Certainly not uncommon to find these issues when you spend your whole life working with all different types of fasteners imaginable!

The amount of times have had to run a tap & die over brand new nuts & bolts is insane ![]()

I especially love the chinathread oddball smaller stuff that’s somewhere between 3.9-4.6mm that no tools on earth will fit ![]()

Worse than working with bloody Whitworth! ![]()

China bolts and nuts are soft as butter anyway so just throw them in the bin to start with ![]()

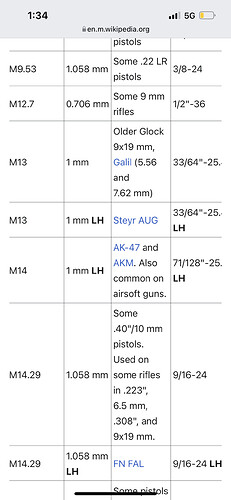

I used to run the gauntlet where I worked in industry. BSW, BSF, UNC, UNF annnd Metric coarse and fine. It was a nightmare trying to fix machinery. Guessing game of what size do we have here today, british old machinery shoehorned with US or metric thread ![]()

![]()

Dunno why it is that was always taught imperial my whole life, and is still all I use to this day!

Metric became popular around 1967, yet I was born 1972 and was taught imperial my whole school years?

Maybe it’s just a “Wait Awhile” State thing ![]()

My “eyechrometer” is highly tuned to be able to look at any imperial bolt/nut and recognise its size immediately ![]()

Metric? dunno what that wizardry is all about…… and I’ve only just turned 50 y.o. ffs ![]()

![]()

Na I was born a bit after you and I was taught both metric and imperial. 9/16" and 14mm same spanner bro ![]() I did some new installations of industry machine so was well thrown in with metric, honestly I like it better than both US and British Imperial sizings. At least I know what I’m dealing with instead of trying to fk around with calipers and 3 different tool sets, thread gauges between US and British. Was such a time waster where I worked used ALL sizes

I did some new installations of industry machine so was well thrown in with metric, honestly I like it better than both US and British Imperial sizings. At least I know what I’m dealing with instead of trying to fk around with calipers and 3 different tool sets, thread gauges between US and British. Was such a time waster where I worked used ALL sizes ![]() Thread repair, 10 different tap sets. If in doubt bore it out and send it metric.

Thread repair, 10 different tap sets. If in doubt bore it out and send it metric.

Can totally relate….but the old “9/16=14mm” and the rest doesn’t work out very well when working on vehicles from the early 1900’s ![]()

Must be precise size tools and NEVER use modern 12 point sockets/spanners on nuts/bolts that were assembled over 100 years ago!

China sizes can absolutely ruin your day. I am lucky to have a really good fastener supplier in the industrial estate I work in, pretty much have their whole m3 and m5 range stocked in my shed now. The amount of Allen head bolts and screws that round out even with the right tools has been ridiculous. Not an issue now as I am alot of the time just swapping to good quality fasteners right away. All started when I designed and printed a hopup, needed some grubs screws and a m3x3 stainless grub screw in a pack of 100 is 4 bucks… it does help that my work has a trade account, with out it they would be 13 bucks… and the counter staff are fellow gelballers too so bonus there also.

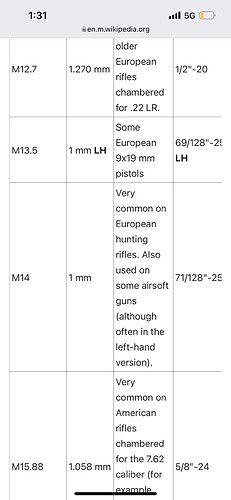

Barrel threads, I know we use reverse 14mm threading. But what pitch is it? 14x1.5?

I want a reverse tap/die set for some 3d printed projects but unsure the exact size. Printer isnt making the threads as well as id like.